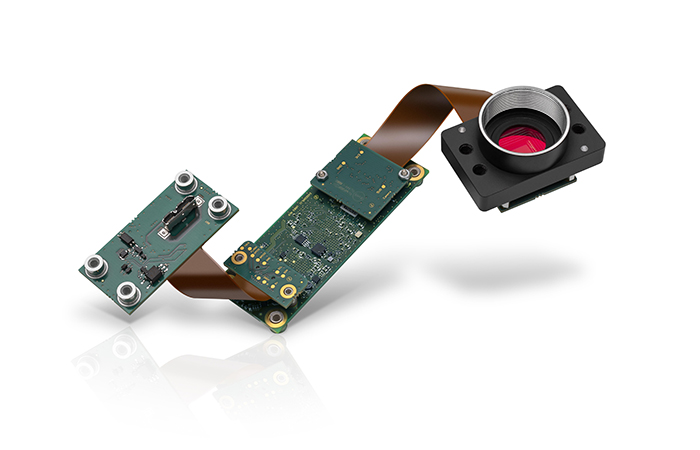

Custom-made products are required whenever standard industrial cameras reach their limits. Especially for small projects, however, development and cost expenditure are often disproportionately high. Thanks to its flexible modular design principle, the new uEye ACP concept from IDS Imaging Development Systems GmbH enables individual, economical solutions to be created – even from single units. With just a few clicks, users can put together their own individual board level camera model using an online configurator and request a quote directly from the manufacturer.

Customers can choose between USB3 and GigE Vision interfaces, extensions such as connector boards (RJ45, M12, MicroB), ribbon cables and lens mounts as well as a large number of different image sensors. This allows the board level cameras to be easily adapted to individual requirements. "With the new uEye ACP models, we offer our customers an economical solution for obtaining individual cameras even for small quantities. They combine high quality, needs-based functionality and simple handling," explains Alexander Klingner, Project Manager Customized Solutions at IDS.

The modular system ensures that long development cycles are avoided. Since almost all components are manufactured by IDS itself, the cameras are usually available at short notice. The components can be further modified by the IDS technology experts on request. Alternatively, the company also offers classic special developments – from customer-specific branding to individual designs and special software adaptations.

Further information:

Comment: Hydrogen requires a long-term mindset

Hydrogen does have and will have its uses. There are always "nay sayers" but these should not be confused with those raising issues that...