How can viscous fluids be sprayed with the FlexFlow™ electronically controlled nozzle system?

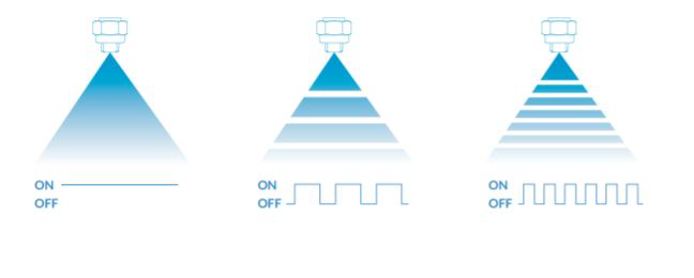

The FlexFlow™ precision spraying control system normally controls electronic nozzles such as the EHP or EHPI. These nozzles have an integrated solenoid valve that allows them to be cycled on and off very rapidly and this offers a great degree of control over the sprays that can be obtained from them.

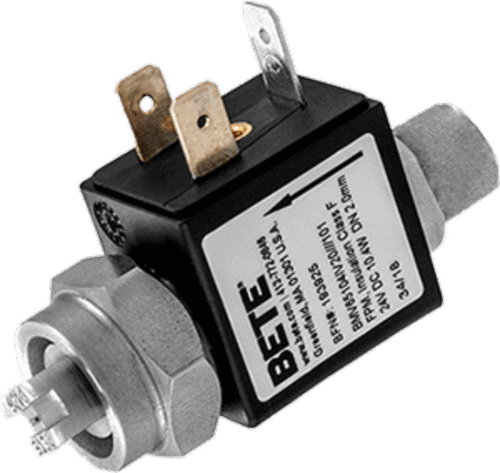

Electric HydroPulse Hygienic (EHP) version

Electric HydroPulse Industrial (EHPi) version

However, despite having the integrated electronic valve, the spray is formed by a simple hydraulic spray nozzle tip and this can pose some limitations on types of fluid that can be sprayed; with hydraulic nozzles, for fluids that have a viscosity higher than water it can be difficult to form good spray patterns at sensible pressures. Generally speaking, the more viscous the fluid, the lower the spray angle will be.

For example, if the spray angle is 90° and the fluid being sprayed is viscous, only a 60° spray pattern can be obtained from that. Eventually, the spray pressure will be so reduced that no proper spray pattern will be formed at all if the viscosity gets too high.

This issue can be overcome by increasing the pressure that the hydraulic nozzle is spraying at. This makes it easier to spray viscous fluids at higher pressures. However, the flow rate will also start to increase with the pressure which can cause further issues.

If relatively low flow rates or highly viscous fluids are required, the fluid pressure may need to be increased too much to form the spray pattern and this can lead to overspraying. It is also important to note that, the smaller the orifice size, the harder it will be to spray a viscous fluid.

In the same situation as mentioned before, where the fluid is viscous and a 10 to 20 bar spray pressure is needed to form a proper spray pattern, a smaller orifice can reduce the flow rate and ensure there is no overspraying. This will, however, turn into a vicious cycle because forming a spray pattern with a viscous fluid becomes even harder and this means that the pressure will need increasing.

Overall, the viscosities that can be sprayed with simple hydraulic nozzles are limited, because the only actions that can be taken are to spray at increasingly high pressures, which can affect the flow rate.

With the electronic nozzles, this can be compensated for in some ways; pulse-width modulation can be used to reduce the flow rate without reducing the pressure. This would make it possible to spray at higher pressures and get more viscous fluids flowing through them. If there is s too much overspraying going on because the pressure has been increased too much and too much flow rate is being obtained, the nozzle can be rapidly pulsed on and off to reduce the flow rate.

There is a greater degree of viscosities that can be put through these nozzles at lower pressures but a limiting factor on the electronic nozzles is that they are restricted to the pressures at which they can spray. This is due to the deliberate sensitivity of the solenoid valve that shuts the nozzle off; a low resistance solenoid is used to cater for the rapid on and off cycling so we are limited to the amount of pressure they can actually hold back.

On the one hand, certain viscosities can be put through these nozzles, more so than with a basic hydraulic nozzle in some situations. On the other hand, if they are having to be sprayed at extremely high pressures that are above 20 bar, then the electronic nozzles cannot cope with that either.

To conclude, it is possible to get viscous fluids up to 25 centipoise flowing through these electronically controlled nozzles. But it can be challenging to set up and there are limitations above that on what can be sprayed through these electronic nozzles.

For more information about electronically controlled nozzles or to discuss alternative options for spraying viscous fluids such as air actuated and air atomising nozzles, please contact SNP.

01273 400092

Microplastics evading capture in wastewater treatment

Can anyone provide a link to a credible peer-reviewed study demonstrating toxicity from microplastics? This report uses words like ´potential´ and...