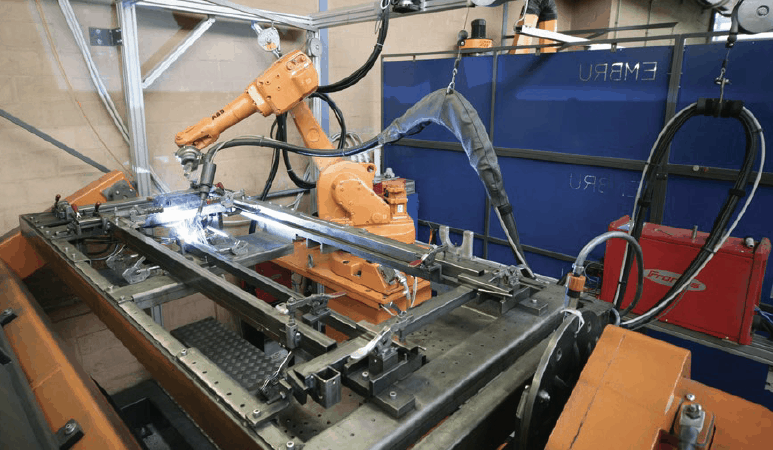

The furniture is mainly made from steel profiles. The challenge the firm faces is welding the intersections and joints so that they are as stable as possible, with no spatter to rule out the need for any mechanical reworking.

In addition, if the heat input is too high when welding the sheet-metal surfaces of drawers and other external parts, heat distortion ensues, which is clearly visible after painting. Conventional arc welding processes such as TIG or MAG welding are therefore unsuitable due to their high heat input.

Invinity to build 20MWh flow battery in UK

Redux flow cells have had nowhere near the R+D effort compared to Lithium ion. They certainly have the potential (pun not intended) for longer...