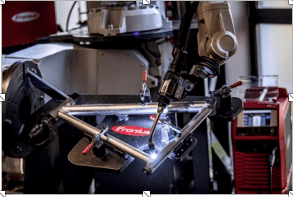

Having the most exact control over the heat input as possible – especially when welding vertical-up seams or joining different thicknesses of sheet metal, such as with pipe-to-flange joints – is essential. PMC mix drive, the new welding process variant, now allows the most precise heat input setting of any process to date, in which high- and low-energy phases are alternated at a low frequency (e.g. SynchroPulse)

Welding vertical-up seams using a standard MIG/MAG power source requires a lot of skill on the part of the welder. In order to prevent the weld seam from sagging, the welding torch needs to be guided in an open triangle (also referred to as a fir tree) so that the weld pool is cooled down by this weaving motion.

Invinity to build 20MWh flow battery in UK

A surprising comment for someone who (I think you´ve said in the past) worked in the industry. National Grid have a variety of reserve service schemes...