Led by Dr Lizhi Xu from HKU’s Department of Mechanical Engineering, outcomes from the research could lead to a range of biomedical applications. The work from HKU has been published in Science Advances and is featured in Nature as a Research Highlight.

Natural tendons are water-rich tissues exhibiting outstanding mechanical strength and durability. Their mechanical properties originate from sophisticated microscale structures involving stiff collagen fibrils aligned in parallel and interlaced with soft water-retaining biopolymers.

Researchers have been trying to use synthetic hydrogels to replicate the structures and properties of natural tendons, but it remains problematic as synthetic hydrogels are usually weak and brittle. According to HKU, resolving this mismatch would enable critical applications in tissue repair, biomedical robots, implantable devices, and many other technologies.

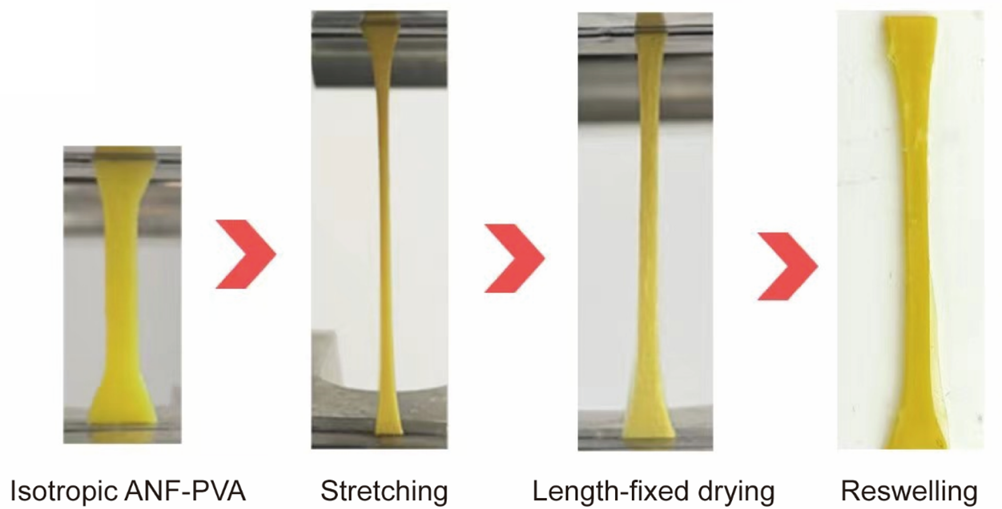

In this study, aramid nanofibres derived from Kevlar were mixed with polyvinyl alcohol for the construction of tendon-mimetic hydrogels. With tensile stress applied during the fabrication process, aramid nanofibres aligned with each other according to the direction of stretching, leading to an anisotropic network mimicking the structural features of natural tendons.

The interactions between the stiff nanofibres and soft polymers further confer high mechanical toughness on the composites. This hydrogel consists of 60 per cent water while showing a Young’s modulus of ~1GPa and strength of ~80MPa, outperforming other synthetic hydrogels, the team said, adding that the surface of the hydrogels can be further functionalised for directing the behaviours of cells or integrating with soft bioelectronic sensors.

“We developed a biomimetic materials platform for advanced biomedical applications. The materials building blocks captured many structural features of natural tendons, leading to amazing properties that are inaccessible with other synthetic hydrogels,” Dr Xu said in a statement. “These hydrogels are not only mechanically strong but also functionalised with bioactive molecules and soft electronic sensors, providing critical capabilities for tissue repair and implantable medical devices.”

Radio wave weapon knocks out drone swarms

Have they tested the effectiveness of the system against the new generation of fibre-optic guided drones now being deployed by both side in the war in...