As far as CNC lathes are concerned, CMZ’s TA series has been on the market for a long time and the thousands of machines sold show that these prismatic bed lathes are a great ally for speeding up production in workshops.

CMZ, a European manufacturer of CNC lathes, had sales last year of €110m. Its core business is the sale of machinery and its wide range of lathes meets the demand of clients with diverse production needs. From companies dedicated to precision turning and high-volume production, to workshops machining large parts, CMZ has a wide offering to meet the highest quality standards. Part of its product range is the TA series, the company’s top selling model with over 2,500 machines sold during its long career.

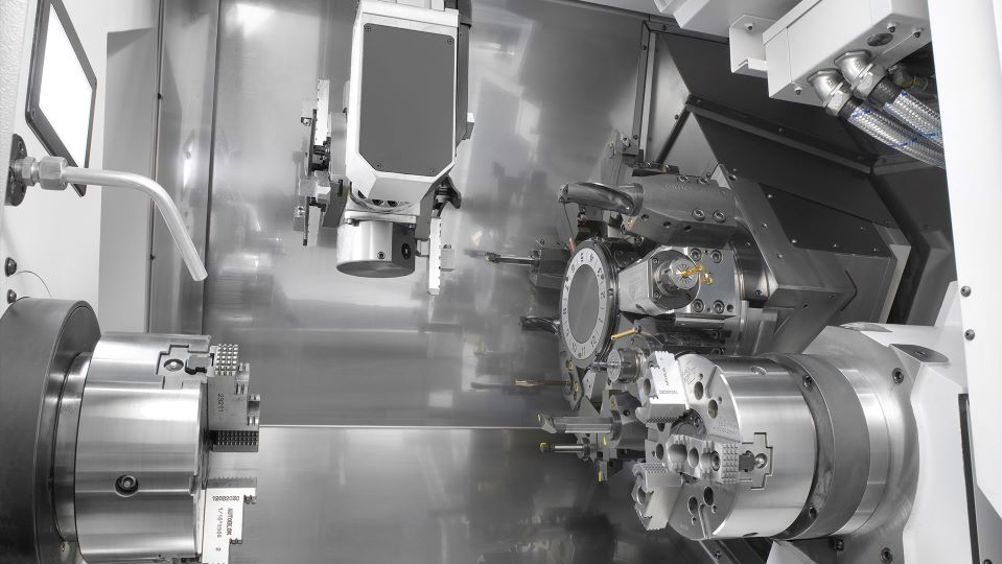

Power, high performance and reliability are some of the words to describe this range of prismatic bench lathes. The lathes in this series can be used to machine different types of parts, such as centre bushings, splined shafts or nuts with very specific metrics. The TA series is also very configurable as there is a choice of benches with Z axis travel of 400, 640 or 1100 Z according to different production needs in each case. Another standard feature of the machine is laser compensation applied during the assembly process, offering high precision and thermal stability.

The turret with integrated motor in the TA series is oil cooled, providing greater thermal stability and it reaches 12,000 rpm with an output power of 75 Nm and 11 kW. Turret movements are robust thanks to blocking with 3 curvic coupling crowns, so the tool holder disc does not move during blocking and unblocking, clamping on the approach and unclamping as it moves away. With this arrangement, tool change can be executed in 0.2 seconds.

This prismatic bench lathe incorporates oil-cooled integrated spindle centre lines. As there are no belts or pulleys, the motor is driven directly, reducing indicators like jump and resulting in a better surface finish on the parts. Machining times are also considerably reduced thanks to this direct coupling and double row bearings which provide greater rigidity and a long lifespan. So, the TA series, like all CMZ lathes, has a lifespan of more than 20 years, providing continuous service and adapting to the different technical characteristics of the machined parts.

In an industry where automation solutions are the order of the day, the TA series offers multiple options for automating short and long batch runs using a Gantry Loader. CMZ also manufactures these solutions and they can be incorporated in its CNC lathes to ensure autonomous work while other workshop needs are being attended to. For example, Gantry Loader GL 20II is a good option for automating the production process, because, in combination with Workstocker WS700, various parts of up to 700 mm can be machined on each line, saving time and staff costs.

CMZ’s TA series has been designed to address the market’s different machining challenges. It has a very wide range of applications, from machining axles to polygon turning or oscillation cutting. For example, oscillation cutting uses sinusoidal movements to facilitate chip breaking and ensure the quality of the machined parts. This option can be implemented in CMZ lathes and in the TA series as well, offering multiple competitive advantages for machining.

In addition to CMZ’s top selling series, the company has a wide variety of CNC lathes to suit market needs. This manufacturer also has a range of multiturret lathes, that is, lathes with two turrets specially designed for high volume production like, for example, the TTL series. In addition, the TD Z2200-Z3200 series has been designed for machining large parts, as it has a bench with more than 2 and 3 metres between chuck and tailstock.

Whatever the production needs, CMZ has a CNC lathe to suit the most demanding requirements. A company with over 500 employees and 6 European subsidiaries providing its customers with a wide product range. The TA series is its top selling machine which has swept the board, a robust, powerful lathe with a lifespan of more than 20 years. See CMZ’s range of lathes on its website.

Emergency law passed to protect UK steelmaking

Although I worked in the steel industry, I didn't get that close to blast furnace operation; however, from what I remember, they tend to stay in...