A semi-detached show-home on the outskirts of Gateshead may seem an unlikely location for a technology revolution. But when this outwardly unremarkable looking building opens its doors in the coming weeks, it will mark a key moment in the UK’s accelerating transition to a zero-carbon economy.

That’s because the development in question - the latest in a series of pioneering projects being led by the UK gas sector - will be the site of the first UK public demonstration of a home fueled entirely by hydrogen.

With the energy used to heat our homes and workspaces accounting for almost 17 per cent of the UK’s total carbon emissions, a switch to low carbon heating systems will be critical to delivering on the UK’s net zero ambitions.

And whilst it’s expected that a wide range of technologies - including heat pumps, electrification, and even geothermal energy from abandoned coalmines (The Engineer, September 2020) will play a part, there is a growing sense across both industry and government that hydrogen will have the starring role.

One of the key efforts driving this has been the BEIS funded and Arup led Hy4Heat programme which was set up in 2017 to explore the feasibility of replacing natural gas with hydrogen for heating and cooking. The aforementioned trial in Gateshead (the Northern Gas Networks led Hydrogen House project) is one of many initiatives funded through the programme.

Hy4Heat manager - Arup civil engineer Heidi Genoni - told The Engineer that the initiative, which has brought together a consortium of energy firms, appliance manufacturers, and researchers, has helped drive a profound shift in attitudes to the role that hydrogen might play in our future energy mix.

What we’re suggesting to government is that from a certain date in the future they mandate that every boiler should be hydrogen ready

Carl Arntzen - CEO, Worcester Bosch

When the programme began, she said, it was as much about ruling out hydrogen as an option as anything else, but as the project team worked its way through key questions on everything from the feasibility of hydrogen appliances to public acceptance, the case for putting the gas at the heart of the UK’s energy transition grew stronger. “As the programme’s progressed we’ve discovered everything is feasible and found a way over various hurdles,” she said. “Everyone’s beginning to realise this really could be a very real possibility.”

One of the keys to this has been the input from some of the biggest names in domestic heating, including the UK’s market leading boiler manufacturer Worcester Bosch, which has developed a prototype hydrogen-ready boiler that’s about to be put through its paces in a series of major trials.

Worcester Bosch CEO Carl Arntzen told The Engineer that when the company began seriously looking into hydrogen around five years ago, it set out to answer two key questions: can it be safely burned in a domestic boiler, and is it possible to make a hydrogen boiler that’s the same size as an existing system?

Artntzen’s team began by looking at what the differences between hydrogen and natural gas might mean in terms of engineering fundamentals.

An early win was the realisation that hydrogen and natural gas have a broadly similar Wobbe index. This is a measure of the amount of heat energy within a given volume of gas. Artnzen explained that whilst hydrogen has a lower calorific value than natural gas, its density is much greater, meaning the same volumes of hydrogen and natural gas will give roughly the same heat energy.

This provided early confidence that not only could a hydrogen boiler be physically the same size (and therefore wouldn’t require future customers to reconfigure their homes) but that it would also be compatible with the existing gas network. “The size of the existing gas network is roughly OK and supplies the same amount of energy whether you supply 100 percent natural gas or 100 per cent hydrogen,” he said.

Nevertheless, the properties of hydrogen did present a number of engineering challenges. For instance, it has a much faster flame speed when compared to natural gas which, said Arntzen, created some initial challenges around how to control the combustion process.

The team also encountered some early problems with “flashback”, a result of both the flame speed and shorter flame height of hydrogen. “The ignition was lighting the fuel upstream of the burner so we were getting a backfire,” he explained. “It was perfectly safe but of course your boiler going bang every few minutes is not really desirable!” Both of these findings prompted a redesign of the burner face to more effectively manage the flow of the gas within the appliance.

Another key challenge was around monitoring and controlling the flame. Whilst existing domestic boilers sense the presence of a flame by detecting the electric current generated by carbon molecules within the gas, the absence of carbon molecules in hydrogen meant they had to look at different solutions for flame detection.

At this point, said Arntzen, it became clear that it wouldn’t be possible to simply convert existing gas boilers to run on hydrogen, and the concept of a hydrogen-ready boiler was born, a system that would initially run on natural gas but which could be switched over to hydrogen with a minimum of fuss. “It goes into your house and burns natural gas, then, four or five years after you have it installed when you get notified that your area is going to be converted to hydrogen we come back in, quickly change a few components, and that boiler’s ready to burn hydrogen.”

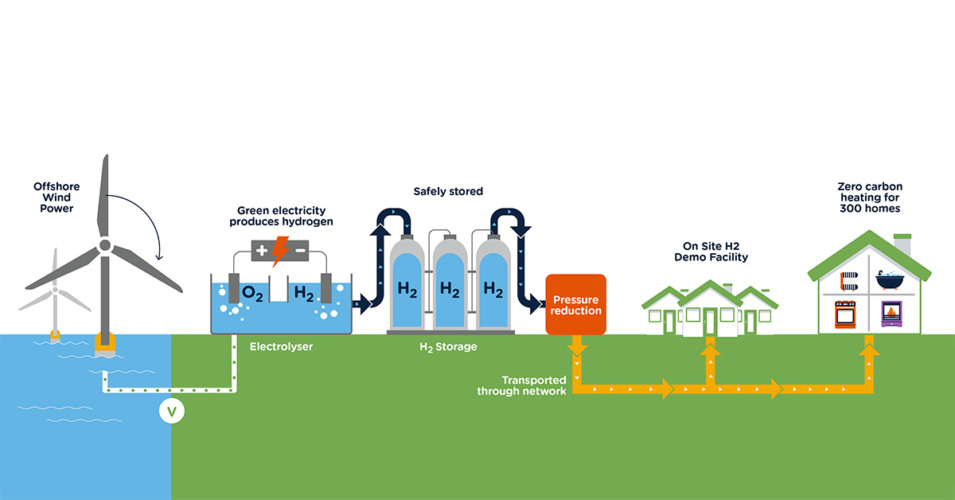

Along with an assortment of hydrogen appliances developed by other manufacturers - including the UK’s other big boiler manufacturer Baxi - Worcester Bosch’s prototype boiler is now being evaluated through two major trials: the Gateshead Hydrogen House project and H100Fife - a hugely ambitious Scottish Gas Networks (SGN) initiative that will see green hydrogen produced by offshore wind powered electrolysers supplied to around 300 homes in Levenmouth, near Fife, on the east coast of Scotland.

As well as providing further evidence of the feasibility of hydrogen appliances, these trials will also shed valuable light on the arguably more complex challenge of getting hydrogen onto the gas networks and into peoples’ homes.

One person wrestling with this particular conundrum is Dr Danielle Stewart, Long Term Strategy Manager for Gas transmission at National Grid.

Stewart told The Engineer that thanks to studies carried out through National Grid’s Hydrogen national transmission system program (HYNTS) there’s now a high degree of confidence that it will be possible to use the existing gas network for hydrogen. However, there are a number of challenges along the way.

For instance, whilst the low pressure (7bar) polyethylene pipes of the distribution network could - she said - be more or less immediately repurposed for hydrogen, there are concerns that hydrogen could lead to embrittlement of the high pressure (94 bar) steel pipes used on the transmission side. Interestingly, earlier studies carried out by the HSE suggest that doping hydrogen with a tiny amount of oxygen could help prevent this from occurring.

National Grid has now embarked on a series of initiatives aimed at fully understanding the integrity, age and condition of its assets before a transition to hydrogen takes place. It is also gearing up for its biggest study yet, FutureGrid, which will see it join forces with gas distribution companies, research groups and others to explore in detail the possibility of converting the national transmission system to hydrogen.

The first phase of this project - which received £10 million funding from OfFGEM just before Christmas - will see a mini offline hydrogen transmission system built from a range of decomissioned assets at DNV GL’s site in Spadeadam, Northumberland. This network will be tested with a range of different natural gas / hydrogen blends, beginning with two per cent hydrogen and working up to 100 per cent. “The aim is to understand the impact of hydrogen in our assets,” said Stewart. “What happens when we put a blend of hydrogen in, what happens with 100 per cent hydrogen? Do the assets cope, do we need to replace them, or intervene in a smaller way?”

Whilst National Grid’s key area of concern is the transmission network, FutureGrid will overlap with a further initiative - the OFGEM funded H21 project - that’s exploring some of the challenges around the distribution network that will bring hydrogen into people’s homes.

Running since 2017 the project has already carried out a number of key trials, including detailed leak testing at purpose built HSE facilities in Buxton, Derbyshire. The next phase will see the construction of an offline distribution network, also at Spadeadam, that will be connected to a row of purpose-built demonstration homes known as HyStreet.

As confidence in the technology grows, so does the conviction that it has a key role to play in the transition of the next decade. And there’s now a palpable sense of momentum to a sector that - just a few years ago - was at the fringes of the energy debate. “There is an urgency,” said Stewart. “There’s a lot of network to transition to hydrogen if that’s the way we go as a country. We’ve got 7.5km of pipelines on the transmission network alone and the distribution network significantly increases that. That doesn’t happen over night”.

What this transition might look like is open to debate, but it seems likely that the switch will begin with an imperceptible blending of the gas into our existing networks. Such an approach, said Stewart, could be key to building up the demand for hydrogen and driving the mass industrialisiation of the technologies that will be required to produce green hydrogen (see box out). What’s more, as conveniently demonstrated by the recently concluded HyDeploy project at Keele University, end use devices are able to function, without any modifications, on a blend of natural gas with 20 per cent hydrogen.

Blending will only get us so far however. And ultimately some big decisions will need to be made on what strategy we use to get to 100 per cent. “There is a question around how you do that,” said Stewart. “Do you start regionalising and breaking the network up and having regions on hydrogen and ultimately joining it all back together? Or do you just keep increasing the blend until you get to 100 per cent?”

Worcester Bosch’s Carl Arntzen believes a phased transition akin to the UK’s conversion from towns gas to natural gas (which took place in the 1960s and 70s) represents the most sensible way forward. “What we’re suggesting to government is that from a certain date in the future they mandate that every boiler should be hydrogen ready, then you can repeat the conversion of the gas network that took place in the 1970s. The concept is to replace it town by town, city by city. The gas grid is a grid, so they can isolate various parts off and start supplying different types of gas to those houses.”

For Worcester Bosch and other appliance manufacturers, such a shift represents a potentially huge market opportunity, however Arntzen was keen to stress that he doesn’t think hydrogen will be the only route to decarbonisation. “Whilst hydrogen will be the appropriate solution for many existing homes, electrifying heating in certain buildings will be the right thing to do,” he said.

Indeed, he believes that low temperature heating systems like heat pumps, along with proper thermal insulation, should be the preferred solution for new build homes, adding that they should be applied immediately rather than waiting for new government regulations to kick in in 2025. “Why not do it now?,” he asked. “Because all of the houses that you build between now and then you’re going to have to refurbish to hit your targets.”

Nevertheless, hydrogen is expected to play a key role, and its case is strengthened by the fact that it’s also being considered by a range of other sectors. “In the last couple of years it’s really gathered momentum,” said Arntzen, “And I think that’s because when you look at the challenge of decarbonising the whole economy there are other sectors such as heavy industry and heavy goods transport where hydrogen is being given serious consideration – if you’ve got a demand in two big sectors of the economy when you add domestic heat to it you can see a serious future for a hydrogen economy.”

We’ve done the feasibility studies, we’ve got the technologies, we’ve now got to get on and start implementing the plans

Heid Genoni - Arup, Hy4Heat Programme Manager

Hy4Heat’s Heidi Genoni agreed that hydrogen’s “all-rounder” credentials add to its attractiveness. “There are several decarbonisarion pathways and success is likely to come from a mixture of all of them,” she said, “Looking at certain criteria in isolation hydrogen doesn’t come first, but it comes second in everything.”

Genoni added that hydrogen is also particularly well suited to the UK, which has a huge existing gas network as well as a large amount of old housing stock where electrification could be more challenging and costly than using gas. “Clearly, it’s less wasteful and better to reuse existing infrastructure where possible,” she said. “The UK has one of the most comprehensive gas networks in the world. We should aim to reuse that existing gas network particularly given that it’s been invested in over the last 20 years by replacing the old iron mains with these new plastic pipes which are perfect for the distribution

of hydrogen.”

Given the levels of expertise in the UK, Genoni is optimistic that the transition to hydrogen could be achieved relatively quickly. What’s needed now, she said, is a joined-up push from everyone involved. “In order to move forward we’ve got to get into a delivery mindset. We know what the scale of the decarbonisation challenge is, we’ve done the feasibility studies, we’ve got the technologies, we’ve now got to get on and start implementing the plans...there is no time to waste.”

Echoing Genoni’s rallying cry, Arntzen called on government to make a firm commitment to the UK’s hydrogen future. “We’ve done four or five years of research, we’re more and more confident that this is completely doable. We now need a decision from government. The future gas network, will it be converted to hydrogen? Give us an answer. Mandate when hydrogen boilers come in and then we can all get on with it and invest in the industrialisation of the prototypes that we’ve developed.”

Green Hydrogen Supply

Although hydrogen is already produced in large volumes, the bulk of this is so-called “brown hydrogen” derived from fossil fuels using processes that the International Energy Authority (IEA) says is responsible for around 830 million tonnes of CO2 emissions per year.

GROWING A GREEN GAS GIANT: INNOVATIONS IN HYDROGEN PRODUCTION

Clearly, if it’s to deliver on its decarbonising potential – and replace a significant chunk of the estimated 78.8 billion tonnes of natural gas used every year by the UK - cleaner methods of production are essential, and the quest to develop this missing part of the jigsaw is now a major driver of innovation.

Initially, this is likely to fuel greater investment in blue hydrogen production, where carbon capture and storage (CCS) is used to capture the CO2 produced by existing processes.

But it’s the developments in green hydrogen production – using giant renewably powered electrolysers to extract hydrogen from water – that are perhaps most exciting of all. Hydrogen produced in this way could – it’s claimed – play a key role in decarbonising industrial processes, domestic heating and transport, whilst offering an elegant method of storing excess renewable energy.

Although there is some debate over how quickly green hydrogen production could be scaled up, a number of large scale projects (Growing a Green Gas Giant The Engineer, July 2020) are making significant progress.

PMI falls as manufacturers feel the squeeze

17 months or two and a half years - which is it?