Researchers at RMIT University in Melbourne, Australia, described how using the material from three million disposable face masks could make just one kilometre of a two-lane road, preventing 93 tonnes of waste from going to landfill.

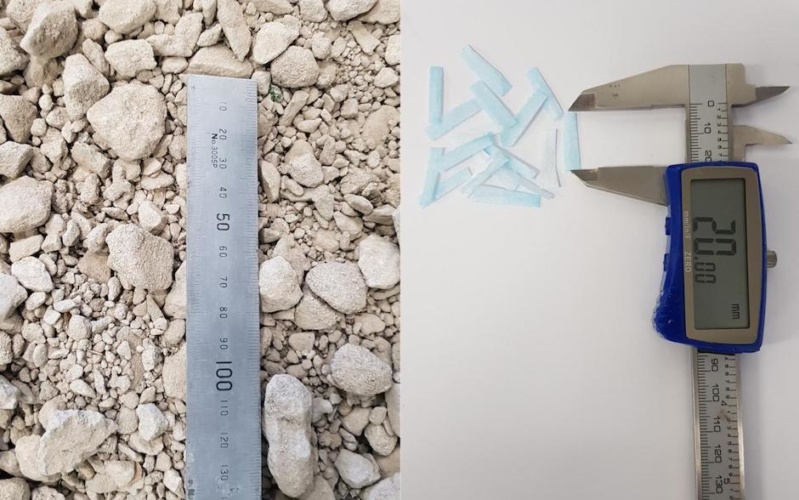

The new road-making material developed by the team is a mix of shredded single-use masks and processed building rubble designed to meet civil engineering safety standards. Their analysis explained how the face masks help to add stiffness and strength to the final product, which is designed to be used for base layers of roads and pavements.

Published in Science of the Total Environment, their study is the first to investigate civil construction applications of disposable PPE (personal protective equipment). First author Dr Mohammad Saberian said multidisciplinary and collaborative approaches were now needed to tackle the environmental impact of COVID-19.

“We hope this opens the door for further research, to work through ways of managing health and safety risks at scale and investigate whether other types of PPE would also be suitable for recycling,” Saberian said.

Roads are made of four layers: subgrade, base, sub-base and asphalt. All of the layers must be strong and flexible to withstand pressures of heavy vehicles and prevent cracking.

Processed building rubble - known as recycled concrete aggregate (RCA) - can potentially be used on its own for the three base layers, but researchers said that added shredded face masks enhanced the material while addressing PPE disposal and construction waste. According to researchers, around 3.15 million tonnes of RCA is added to stockpiles each year rather than being reused.

The optimal mixture identified by the study was one per cent shredded face masks to 99 per cent RCA, and is said to have performed well when tested for stress, acid and water resistance as well as strength, deformation and dynamic properties.

While the study was conducted with a small amount of unused surgical masks, other research has investigated effective methods for disinfecting and sterilising used PPE such as the ‘microwave method’, where masks are sprayed with an antiseptic solution then microwaved for one minute.

In related work, the researchers investigated the use of shredded masks as an aggregate material for making concrete, which is said to have produced ‘promising preliminary findings’. Team leader Professor Jie Li said that the team were inspired after noticing so many discarded masks littering local streets.

“The COVID-19 pandemic has not only created a global health and economic crisis, but has also had dramatic effects on the environment,” said Li. “If we can bring circular economy thinking to this massive waste problem, we can develop the smart and and sustainable solutions we need.”

Guest blog: exploring opportunities for hydrogen combustion engines

"We wouldn't need to pillage the environment for the rare metals for batteries, magnets, or catalisers". Batteries don't use rare...