Engineers in Korea have developed organic adhesives which, they claim, are even tougher than the biological glues used by shellfish like mussels to attach themselves to rocks, the hulls of ships and static marine structures and to larger sea creatures. Like these natural glues, the substances retain their adhesion underwater and on moist surfaces, making them potentially useful in bio-engineering and medicine, where conventional chemical adhesives struggle.

Developed by Prof Hoon-Eui Jeong in the School of Mechanical Aerospace and Nuclear Engineering at the Ulsan National Institute of Science and Technology (UNIST), the glue is technically referred to as a wet adhesive, because it is works under wet conditions. As well as being very strong, it can be made to unstick easily; moreover, unlike natural protein adhesives derived from sources like shellfish, it does not require any treatment of the surfaces to be stuck together.

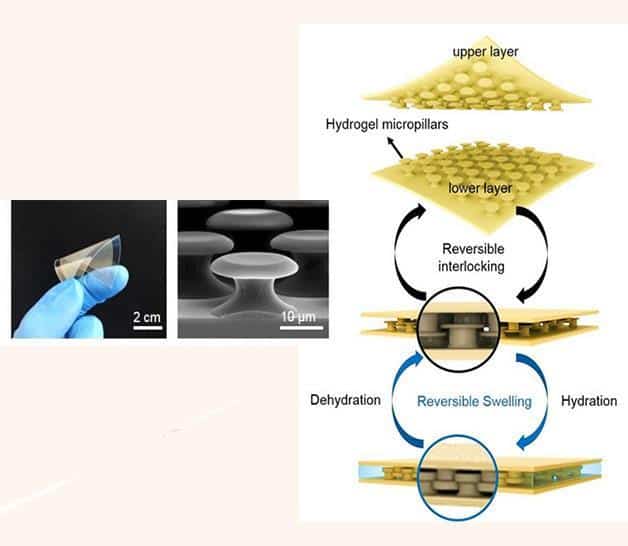

The adhesives are based on hydrogels, and their adhesive properties derive from structures on the surface of hydrogel films. The researchers refer to these as "micro-hooks", but in fact they more closely resemble tiny flat-topped mushrooms. These films were made by casting a hydrogel resin, polyethylene glycol dimethacrylate (PEGDMA) into a mould made by etching a silicon wafer, forming the mushroom shaped structures, which were about 10µm across and stood about the same distance above the surface of the film.

In a paper in ACS Macro Letters, the UNIST team explains how the films were made, and how their structure gives them their outstanding adhesive qualities under wet conditions. When two sheets are placed together, the head of each mushroom shape interlocks with heads on the other film. When wet, the PEGDMA swells, locking the structures together firmly so they cannot be dislodged by either normal (perpendicular to the surface) or shear (in line with the surface) forces. When material dries out, the mushrooms shrink, allowing the adhesion to release.

"In contrast to other wet binding systems, the current interlocking mechanism does not involve any complicated surface treatment or chemical moieties, thus allowing for a simple yet efficient route to strong and reversible wet adhesion in a cost-effective manner," Prof Jeong said.

Invinity to build 20MWh flow battery in UK

Redux flow cells have had nowhere near the R+D effort compared to Lithium ion. They certainly have the potential (pun not intended) for longer...