This is the fifth of eight articles from our Nozzle Knowledge series in which we look at the basics of spray nozzle systems. If you would prefer to watch a video version, please click here. Or, if you would like to download a pdf version, please click here.

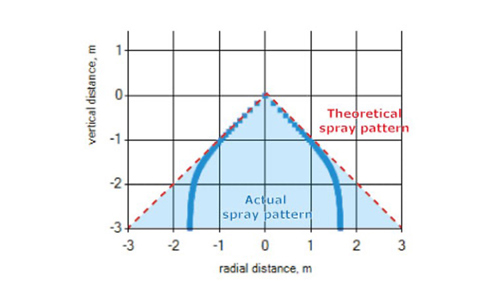

The spray angle of a nozzle dictates the width of the spray pattern and, in theory, basic trigonometry can be used to calculate the distribution of the fluid being sprayed. In reality, however, this doesn’t work. While the theoretical pattern may be true very close to the nozzle, it often doesn’t hold the further away from the nozzle orifice it travels.

So, what factors affect theoretical spray patterns?

1. GRAVITY

Gravity starts to draw in the spray pattern and reduce the fluid distribution.

2. WIND & GAS FLOW

Wind and gas flows will start to move the theoretical, trigonometrically derived spray pattern away from where it is supposed to be.

The effect of wind and gas flow will be enhanced the smaller the drop size is; the smaller the drop size, the bigger this effect is going to be.

3. FLUID PROPERTIES

The most important fluid property is viscosity, and this tends to reduce the spray angle of the nozzle.

Spray nozzle spray angles are calibrated on water. This means that if a more viscous fluid is being sprayed, the spray angle will be reduced.

The specific gravity of the fluid tends to reduce the effects of the gravity drawing in the spray pattern because the liquid being sprayed is denser. In many respects, spraying heavier and denser liquids will overpower some of the effects and get closer to the theoretical spray pattern.

4. PRESSURE

Some nozzles have a variation in their spray angle depending on what pressure they're being sprayed at.

This is particularly true for tangential whirl hollow cone nozzles. Their spray angle will vary quite considerably with the pressure of which they are spraying.

For other nozzles, however, this is less important.

Here at SNP, we have software that can help work out where the variations will occur between the theoretical trigonometry of what the derived spray pattern will be and the actual spray pattern. Please don’t hesitate to get in touch if you need more information or some help to ensure your spray system works as expected.

About SNP

SNP aims to take the hassle out of procuring small engineering components such as spray nozzles with expert advice and product specification.

SNP supplies spray nozzle solutions to industries worldwide, including the largest engineering, food processing, chemical and petrochemical companies, as well as a vast array of small and medium sized enterprises (SMEs). The company’s product range includes tank washing nozzles, hydraulic nozzles, air atomising nozzles, custom piping assemblies and spray accessories as well as disinfecting and washdown systems.

SNP is as skilled in advising design engineers at the beginning of projects as it is recommending and supplying replacement products that may be needed in a hurry. The company can also provide innovative custom solutions, including using non-standard materials. SNP holds ISO 9001 certification.

SNP is an exclusive distributor for US spray nozzle manufacturer BETE, for pre-treatment specialist Uni-Spray, specialist paper industry nozzle manufacturer ML Gatewood and tank cleaning systems manufacturer Dasic. In addition, SNP supplies specialist washdown and disinfecting equipment from Lafferty Equipment and Guarany. Orders are handled quickly and efficiently from SNP’s own dedicated fulfilment facilities in the Midlands.

01273 400092

info@spray-nozzle.co.uk

www.spray-nozzle.co.uk

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...