The data center market has seen a massive growth in recent years. Spurred by a growing adoption of cloud technologies, AI, IoT, 5G and big data, new data centers are being built across all continents at fast pace. Whether they are in-house data centers for some of the largest and most influential companies, or built by specialized vendors offering infrastructure services, data centers fulfill a critical role in maintaining the continuity of a business. Downtime of a data center can have an enormous economic impact and needs to be avoided at all costs. In addition to financial loss, reputational damage can be equally impactful, especially when the data center is supporting customer-facing services.

Guaranteeing uptime has become increasingly complex for data centers. With so much mechanical, electrical and electronic infrastructure under one roof, overheating is a major concern, not only because the infrastructure is not using the energy efficiently, but also because overheating can cause a complete shutdown of servers, impacting users around the world, or even data or equipment loss. One of the most reported incidents is the 2013 overheating of a Microsoft data center operating some of its cloud services, including Outlook, which led to services being lost for 16 hours.

MAINTENANCE INSPECTIONS WITH THERMAL IMAGING CAMERAS

The maintenance of a data center today involves much more than IT operations. Power distribution systems and cooling infrastructure are also essential for keeping the data center up and running, and for preventing mechanical or electrical failures and resulting outages.

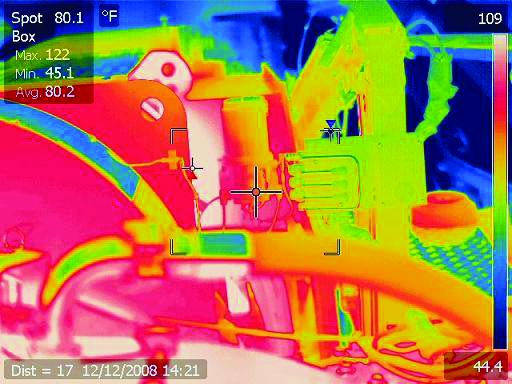

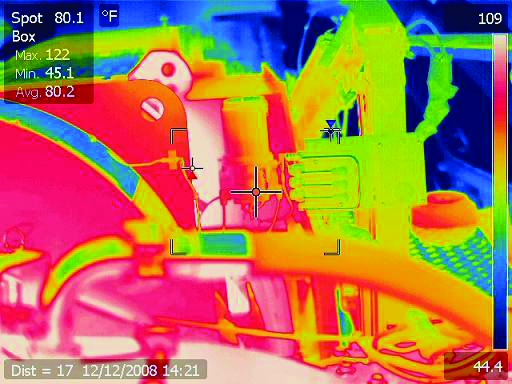

Many systems that are critical for the data center’s operation heat up before they fail. Temperature is an important indicator of energy consumption and equipment operation, which is why infrared thermography (thermal imaging) is an ideal tool to inspect power consumption, electrical installations, cooling equipment and computing hardware.

Periodic inspections with a thermal imaging camera have become indispensable in predictive and preventive maintenance programs. Thermal cameras help maintenance staff to detect problems in electrical switchgear, motors, HVAC infrastructure, uninterruptible power supplies (UPS), power distribution units (PDU), batteries and generator equipment and all electrical devices that feed the server systems, before these problems turn into serious failures or downtime.

With cloud computing becoming the new normal, and as data centers are growing to great scales, the need for higher computing density and power efficiency is growing as well. Data center owners are seeking ways to increase their capacity, but they also want to reduce costs and energy. Thermal imaging can give them important information on how to optimize energy and space requirements, without causing overheating.

In short, regular inspections with thermal imaging cameras can help maintenance staff to:

• Find and fix hidden problems before they turn into unplanned downtime.

•Reduce the chance of component degradation going unnoticed due to overloaded circuits or loose connections.

•Prevent equipment breakdowns

•Optimize energy management and space allocation

WHAT IS THERMAL IMAGING?

A thermal camera is a non-contact device that detects infrared energy (heat) and converts it into a visual image. Infrared radiation lies between the visible and microwave portions of the electromagnetic spectrum.

Any object that has a temperature above absolute zero (-273.15 degrees Celsius or 0 Kelvin) emits radiation in the infrared region. Even objects that we think of as being very cold, such as ice cubes, emit infrared radiation. Thermal cameras turn this invisible energy into something that can be seen on a screen and measured.

The themal spectrum

THE BENEFITS OF THERMAL IMAGING

Why would you choose a FLIR thermal imaging camera? Sure, there are other technologies available to help you measure temperatures – infrared thermometers or thermocouples to name only two. But no other tool is as powerful and efficient as a FLIR thermal imaging camera.

SEE THE WHOLE PICTURE

Unlike IR thermometers or thermocouples, thermal imaging cameras enable you to scan large areas for hot spots or temperature differences. Without a thermal camera, it’s easy to miss critical parts like air leakages, areas with insufficient insulation or water intrusion. A thermal imaging camera can scan entire electrical installations, buildings, heating or HVAC installations. It never misses a potential problem area no matter how small this might be. They also allow you to compare temperatures of components in the same environment more easily.

Maintenance of data center installations can be labor-intensive. Because they can easily see larger surfaces, thermal imaging cameras can be the solution to reduce maintenance time speed up inspection rounds, and still see all impending failures, before they turn into costly defects.

INSPECT WITHOUT SHUTTING DOWN

Thermal imaging is a non-contact technology. This is a safe method, because maintenance personnel can keep a distance without having to touch hot items. But it also means that inspections can easily be carried out while the equipment is still running or under load. There’s no need to foresee costly downtime. Some inspections, for example rotary UPS systems, can only be done during operation, which makes the thermal imaging camera an ideal tool for online inspections.

REPORT LIKE A PRO

Thermal imaging cameras allow users to make professional, more insightful reports of their inspections that also look great for management and customers. Users can compare current inspections with historical data and discover trends. Features like templates, batch processing, image editing and route planning further enhance the use-friendliness of today’s reporting solutions.

THERMAL IMAGING APPLICATIONS

Thermal imaging is the perfect technology to tackle the wide range of maintenance and inspection jobs for data centers.

ELECTRICAL AND MECHANICAL SYSTEMS

Thermal imaging cameras can be used to inspect a variety of electrical or power generation-related systems. Heat is an important indicator for defects in electrical installations. When current passes through a resistive element, it generates heat. Over time, the resistance of electrical connections can increase, due to loosening and corrosion for instance. The corresponding rise in temperature can cause components to fail, resulting in unplanned outages.

Electrical systems can also suffer from load imbalances and increases in impedance to current. Thermal inspections can quickly locate hot spots, determine the severity of the problem, and help establish the time frame in which the equipment should be repaired.

Thermal imaging cameras will help you to spot issues with:

•Overheated connections

•Overloaded or imbalanced circuits

•Damaged switches

•Faulty fuses

•Power supplies

•Battery systems

•Generator systems

•Uninterruptible Power Supplies (UPS)

•Transformers

•Electrical panels

•Resistive load banks

HVAC AND COOLING SYSTEMS

To run smoothly and efficiently, data centers need perfectly air-cooled conditions. Data centers are typically making use of a hot aisle/cold aisle layout principle. Server racks are lined up in aisles with the front sides facing each other. The cold aisles get cold air directly from the Computer Room Air-Conditioning (CRAC) unit from the bottom of the raised floor. The cool air cools down the servers on the racks. Meanwhile, the backs of the servers vent out hot air in the hot aisle, which then returns to the CRAC unit. Thermal imaging has become increasingly important to verify the proper hot aisle/cold aisle operation, especially because data centers today are condensing more servers into their racks. Thermal cameras will enable users to see problems such as misaligned ductwork and electrical faults, and then make decisions about corrective actions. HVAC inspection with a thermal imaging camera can help to:

•Monitor server rack temperature distribution patterns

•Locate misrouted and leaking ducts

•See electrical or mechanical CRAC unit defects

•Confirm the source of energy losses

•Find missing insulation

•Discover AC condensate leaks

•Find internal server fans which are inoperable or damaged

RENEWABLE ENERGY

Data center operators are increasingly improving their use of renewable energy sources, including solar and wind power. These renewable power sources enable data centers to reduce their environmental impact, whilst meeting long-term sustainability goals.

SOLAR POWER

The solar panel, the most important part of a solar system, must be reliable and capable of producing electricity for years on end. Unfortunately, solar panels are susceptible to wear. Maintenance professionals therefore use thermal imagers to inspect solar panels installed on rooftops or in solar parks to quickly pinpoint solar panel problems down to cell level. Anomalies can clearly be seen on a crisp thermal image and - unlike most other methods – thermal imaging cameras can be used to scan installed solar panels during normal operation. Thermal imaging cameras also allow users to scan large areas within a short time frame.

WIND POWER

Wind turbine components are susceptible to wear and can break down. That’s why preventive maintenance and periodic inspections are so important. Thermal imaging is the only technology that allows users to inspect all electrical and mechanical components of the wind turbine and the surrounding electrical system, so they can detect a problem before a breakdown occurs.

A thermal imaging wind turbine transmission survey performed at a 50-meter height

FIRE PROTECTION

Although data center fires are relatively rare, they can have a devastating impact. Data centers may be equipped with fire alarms and firefighting systems, but once a fire starts, asset damage is almost certain. Fixed thermal imaging cameras can identify hot spots before they ignite and provide an early warning response to avoid a full-on destructive fire before assets are harmed or safety is compromised.

PHYSICAL SECURITY

Thermal cameras not only detect hot spots or temperature differences. They also help protect a physical perimeter against unwanted intruders or trespassers. As data centers operate 24/7, they need effective solutions to help them monitor the premises and detect threats around the clock. Thermal security cameras that offer high contrast, high resolution and long detection ranges are ideal for data center deployments.

Unlike standard video cameras, thermal cameras can see in most adverse weather conditions– such as light rain, fog, smoke, or total darkness. When integrated with video analytics, thermal cameras can distinguish between a human or vehicle. When paired with radar, customers gain redundancy and reduce the likelihood of a false positive. By combining thermal cameras with HD visible cameras, remote operators can review thermal and visible video streams of the scene for improved alarm verification and intruder identification.

THERMAL IMAGING SOLUTIONS FROM TELEDYNE FLIR

HANDHELD THERMOGRAPHY CAMERAS

Armed with a FLIR thermal imaging camera, maintenance crews can easily diagnose a wide range of problems across their data center facility. Available in a wide variety of sizes and image resolutions, FLIR thermography cameras always offer the highest accuracy and user-friendliness to meet the needs of maintenance professionals.

THERMAL STUDIO SOFTWARE WITH ROUTE CREATOR

FLIR Thermal Studio Suite is state-of-the-art analysis and reporting software designed to help data center maintenance teams manage thousands of thermal images and videos. Whether you use handheld thermal cameras or unmanned aircraft systems (UAS), the FLIR Thermal Studio suite of software provides the automation and processing capabilities you need to streamline workflow and increase productivity. The optional Route Creator plugin allows users to plan inspection routes in advance, complete inspections more efficiently and reduce reporting time by 50%.

Keep your thermal camera in optimal performance condition and avoid unforeseen downtime with a FLIR CARE service package. Whether you are looking for a performance verification service or a traceable calibration adjustment service, FLIR CARE’s traceable calibration services have you covered.

FLIR PROTECT Extended Warranty and Service Packages give you the peace of mind that your camera is protected from material defects and issues for three years after your factory warranty expires. Choose FLIR Protect+, FLIR Protect Pro, or FLIR Total Protect to bundle a discounted FLIR CARE Service with your FLIR PROTECT extended warranty.

ABOUT FLIR, A TELEDYNE TECHNOLOGIES COMPANY

FLIR, a Teledyne Technologies company, is a world leader in intelligent sensing solutions for industrial applications with thousands of employees worldwide. Founded in 1978, the company creates advanced technologies to help professionals make better, faster decisions that save lives and livelihoods. For more information, please visit www.teledyneflir.com or follow @flir.

McMurtry Spéirling defies gravity using fan downforce

What a fun demonstration. I wonder if they were brave enough to be in the car when it was first turned over. Racing fan cars would be an interesting...