Spray nozzles may be a small component of complex processes but their performance is critical to success. Nozzles that are not thoroughly inspected and regularly evaluated for wear or damage can cause operations to fail or lead to thousands of pounds in wasted resources. The cost of lost product resulting from quality control problems, from use of additional chemicals and energy, unscheduled production downtime and extra labour quickly escalates.

Most spray problems are avoidable through a simple nozzle maintenance programme which checks for wear or damage and enables timely replacement.

Flow rate monitoring

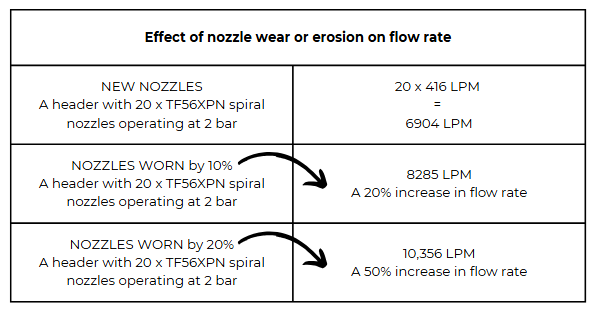

Monitoring the flow rate of a nozzle is one means of identifying if it showing signs of wear or damage. As per the table below, a 10% increase in the orifice of a spray nozzle from wear or erosion can result in flow rate increasing by 20%. This soars to 50% if nozzles are worn by 20%.

Evaluating nozzles by eye alone (or using the tried and test method of a bucket and stopwatch) is inaccurate and time-consuming.

A simple tool for measuring flow rate

The SC-2 is a small portable and easy to use nozzle spray calibrator, useful for installation and setup as well as maintenance checks for other similar nozzles in a production line.

About the Spray Calibrator

The SpotOn® Sprayer Calibrator SC-2 delivers quick and precise flow rate measurement for individual spray nozzles. It can accurately check flow rates between 0.08 and 8.52 litres per minute, ensuring even spray distribution and reducing spray media wastage.

Design Features

Key Benefits

To find out more, click here.

To learn more about how to maintain spray nozzles, download the guide here.

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...