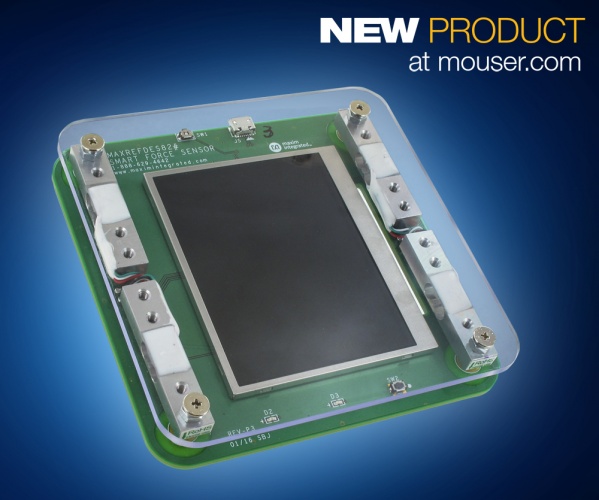

Mouser Electronics, Inc. is now offering the MAXREFDES82 smart force sensor reference design from Maxim Integrated. The MAXREFDES82 reference design features a next-generation industrial, smart force sensor that helps designers rapidly evaluate and deploy new human-machine interface (HMI) devices. The design measures mass up to 780g, as well as the center of mass of the object on it, allowing it to operate as both a weigh scale and a touch interface with force sensing for instrumentation and industrial control.

Maxim’s MAXREFDES82 smart force sensor reference design, available from Mouser Electronics, provides both downward force and center of mass by collecting responses from four load cells using the Maxim MAX11254 24-bit, 6-channel analog-to-digital converter (ADC). This highly integrated ADC works with the load cells to provide second and third dimensions of information about objects on the sensor. The system includes a 3.5in thin-film-transistor (TFT) liquid crystal display (LCD) module that digitally shows the forces on each load cell and the total force applied on the top plate. The LCD module also displays the force magnitude and the coordinates of the force center. The design incorporates a 32-bit STMicroelectronics STM32F4 microcontroller with an ARM Cortex-M4 core to control the ADC and LCD module.

The MAXREFDES82 reference design consumes less than 50mA during normal operation and is powered by a USB port. A PC-side graphical user interface (GUI) program is also included to facilitate the human interface input demonstration and development. The design includes source files for the microcontroller to enable developers to quickly evaluate and customize the design for their specific applications with minimal firmware or hardware changes.

Radio wave weapon knocks out drone swarms

Probably. A radio-controlled drone cannot be completely shielded to RF, else you´d lose the ability to control it. The fibre optical cable removes...