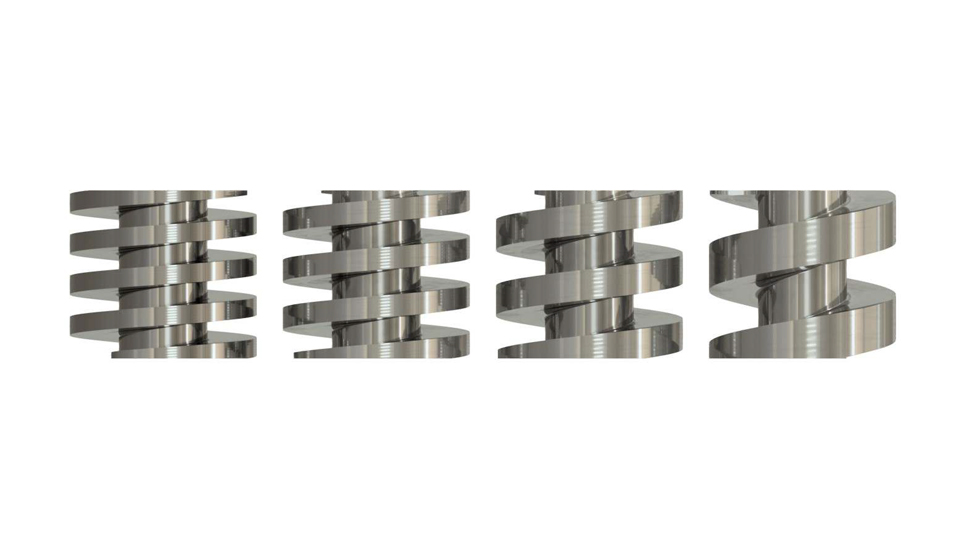

HTS Hygienic Twin Screw Series

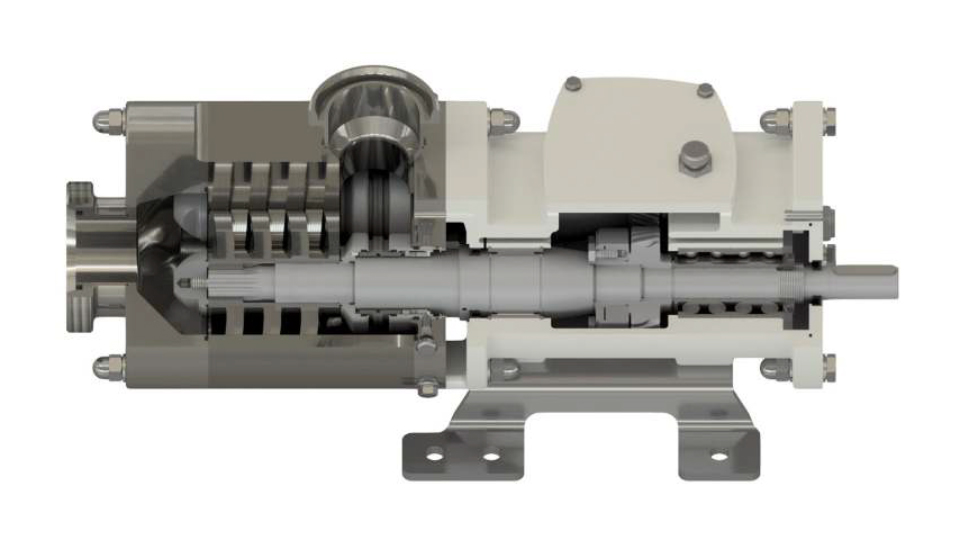

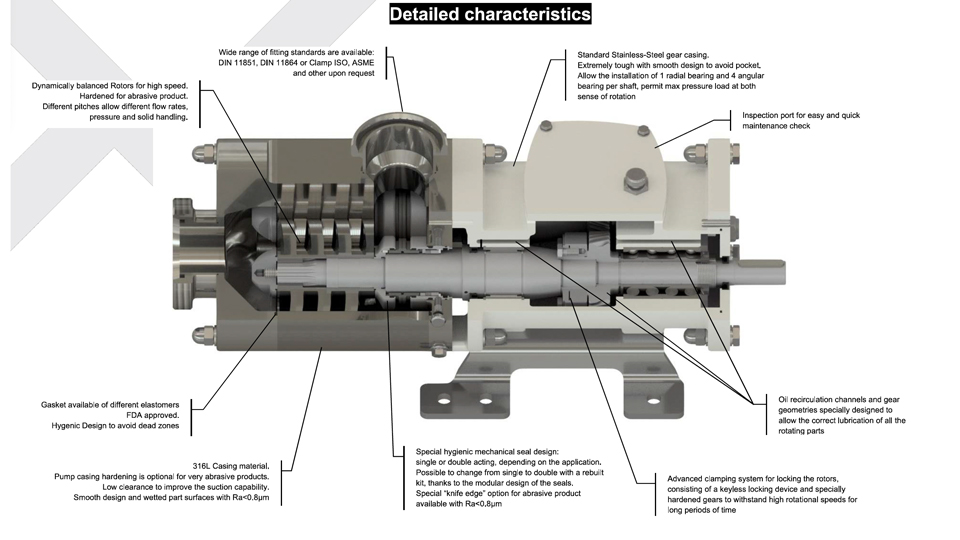

The HTS is the new state-of-the-art of hygienic twin screw technology designed to achieve the maximum level of sanitation for food and pharmaceutical market.

The pump design is extremely tough thanks to oversized shaft and bearing dimensions.

The main features of the twin screw pumps are:

- Gentle treatment and low pulsations due to axial conveying of product

- High suction capability with low NPSHr values

- The rotors and the pump casing are not in contact: dry run is possible with flushed seals

- CIP and process with only one pump

- High pressure and high flow rate with a very compact pump

- Suitable for very viscous liquids (up to 1.000.000 cps)

- Suitable to handle solids and/or abrasive products

- Easy and quick maintenance

VERSION AND OPTION

VERSION AND OPTION

Casing Material

Base Materials

- AISI 316

Heat Treatments:

- Kolsterising

Materials of the sealing shaft

Base Materials:

- ASIS 630

- Duplex (F51) or Superduplex (F55) on request

Rotor Materials

Base Materials:

- ASIS 316

- Duplex (F51) or Superduplex (F55) on request

Heat Treatments

- Kolsterising

Gasket materials

Base Materials:

- H-NBR

- EPDM

- FPM

- FFPM

Base Plates

- Standard Baseplate

- Standard Baseplate with 3-A Adjustable feet

- Hygienic Base Frame (meets hygienic recommendations)

Connections

- DIN 11851

- DIN 11864-1 / DIN 11864-2 / DIN 11864-3

- Clamp ISO 2852, Clamp ASME-3A, Clamp DIN 32676

- RJT

- SMS 1145

- Macon

Sealing System

- Single acting hygienic balanced mechanical seal (special design)

- Double acting hygienic balanced mechanical seal (special design)

Control Devices

- Control Panel

- Control Panel with inverter

- Drive with integrated inverter

Equipment and Optional

- Heating Jacket

- Quench Pot Flushing

- Drive Cover

Certifications

- CE

- (EHDG AND 3-A Certifications on development)

Features of Use

Operating Range

Flow:

- Up to 200 m/h

Pressure

- Up to 25 Bar

Temperature

- From - 40*c until to 150*c

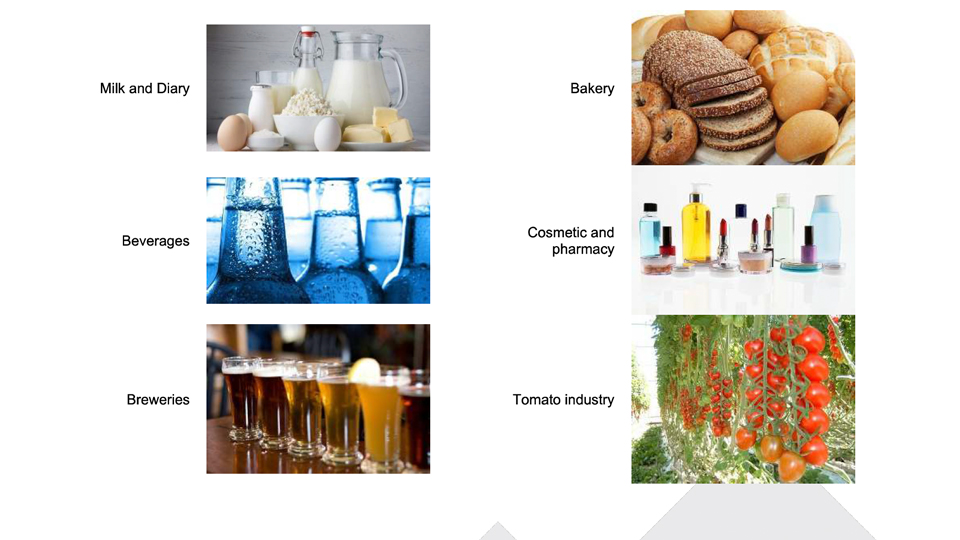

Typical Applications

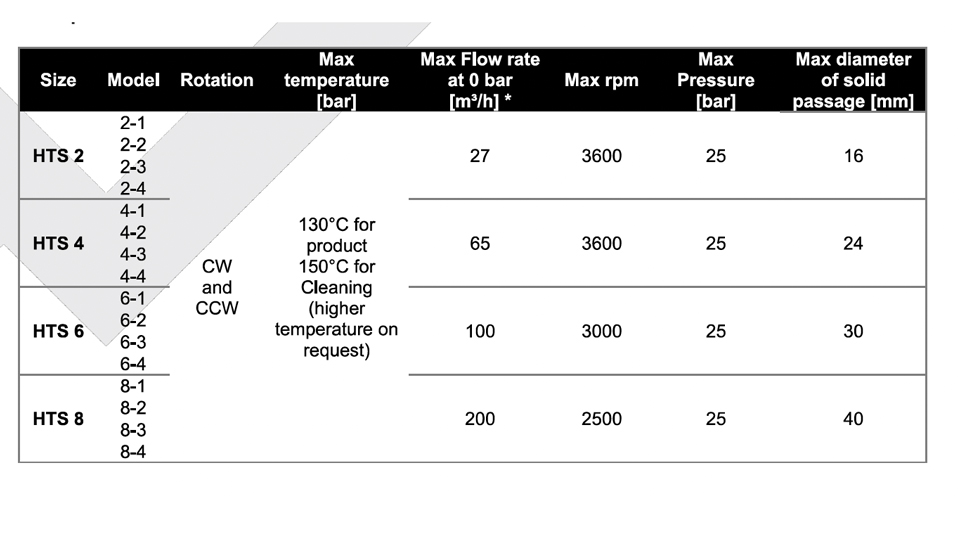

TABLE OF MODELS

TABLE OF MODELS

Flow and Pressure

*Based on Largest Pitch

PMI falls as manufacturers feel the squeeze

17 months or two and a half years - which is it?