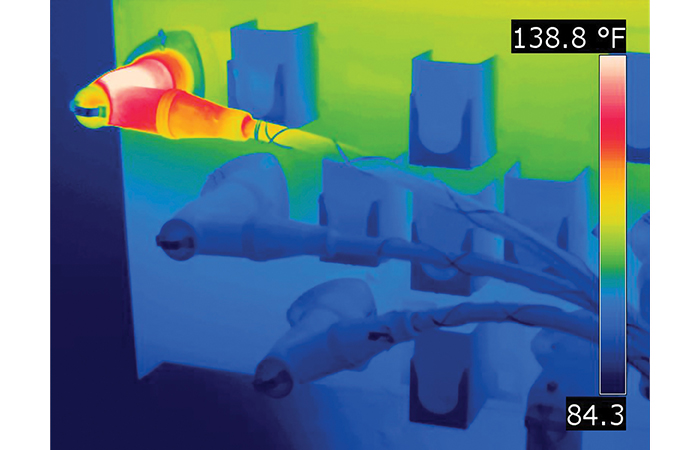

Repairing or replacing a transformer is expensive. As FLIR explains in a new technical application note, a thermal camera quickly pays for itself as it enables utility companies to fix problems before they result in a shutdown.

Regular thermal inspection can rapidly detect and locate overheating areas on the surface of a transformer or hot spots on electrical connections. And once an overheating component is detected it can be investigated further with complementary methods such as ultrasonic, vibration or oil analysis.

The benefits of catching hot spots early include extending the life of otherwise well-functioning equipment and prevention of equipment failures that could lead to widespread outages. Costs are reduced through maintenance as opposed to replacement of damaged equipment and safety is improved by reducing the risk of fires or explosions that may result from transformer failures.

Application spotlight link:

Click here and register to access technical articles and white papers from this company

Fusion inches closer as ITER completes magnet system

I believe the purpose of ITER isn't to make usable power, it is a research project which will be used to design the first generation of actual...