A pre-assembled plug that combines the benefits of easier handling and faster installation with the proven reliability and performance of Lee expansion plugs, was among the new products to be exhibited by Lee Products at the recent Farnborough International Air Show.

The Lee Plug is simply the most effective and field-proven method of ensuring a permanent leak-proof seal to drilled holes in critical applications, including aviation, machine tools, down-hole tools, moulds, or any application requiring a permanent seal.

The operating principle is based on a cylindrical plug with a tapered hole part-way through its centre and small grooves on its outside diameter. It is slipped into a reamed counter-bore in the product and then a tapered pin is driven into the plug until the ends of the pin and the plug are flush with each other. Controlled expansion causes the lands and grooves of the plug to ‘bite’ into the surrounding material forming independent seals and retaining rings. The result is a positive, reliable and permanent, leak-proof seal for both liquids and gases which as a simple and proven principle, contributes to significant improvements in the design and manufacture of all fluid devices.

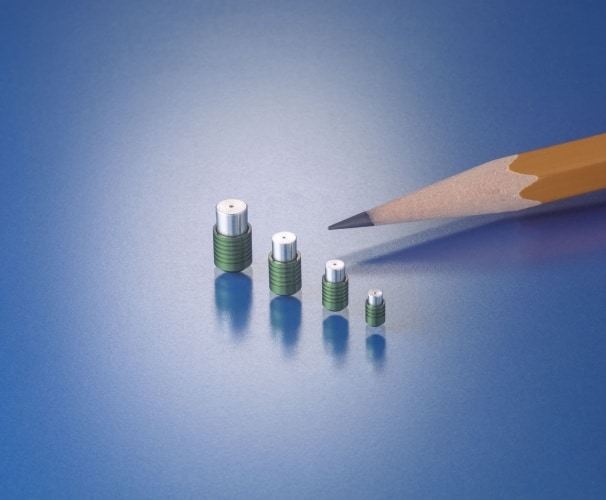

Lee’s pre-assembled plugs are available in four sizes of .093, .125, .156 and .187in diameter, are designed for high-proof pressures up to 12,000psi and are compliant with RoHS, REACH, WEEE and ELV requirements. Assembly time for the pre-installed plugs is approximately 25 per cent less than for the standard short aluminium Lee Plugs.

Arriva makes £300m tri-mode train order with Hitachi Rail

This development shows up the lack of a comprehensive nationwide network of electrified lines for passenger services and freight The glacial speed of...