TIG welding made easy: 10 kg, extensive range of functions

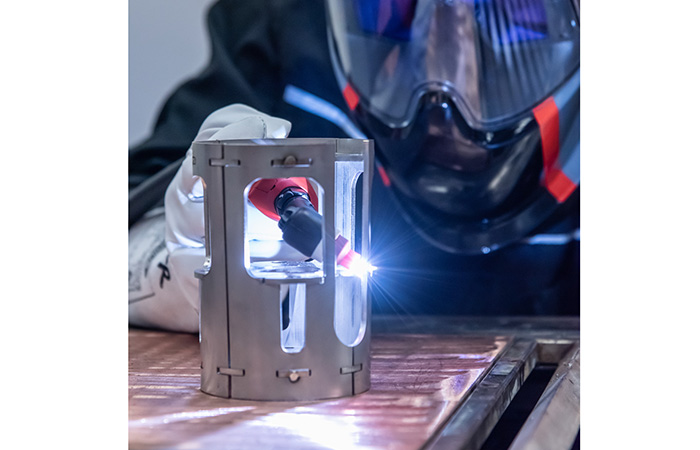

Tungsten inert gas (TIG) welding. There’s simply no other welding process that can beat it in terms of cleanliness or weld seam quality. To make TIG applications even easier, Fronius has developed the TransTig 170/210. This compact manual TIG welding system boasts an extensive range of functions to deliver perfect welding results.

TIG welding can be used in a variety of applications. The process is suitable for all metals, thin sheets, out-of-position welding and root pass welding. Welding can be performed with or without a filler metal and the process is of particular benefit to industry users, such as plant and container construction, pipeline construction and also maintenance, assembly and repair. Since stainless steel and aluminium are primarily used in these sectors, the TIG process wins praise due to the high quality “look and feel” of its weld seams. The TransTig is also particularly impressive for mobile applications, as its lightweight and easy to handle design aids users with their varied tasks.

Reliable arc even with an unreliable mains supply

The new generation of TIG DC devices from Fronius strikes the perfect balance between a compact design and a wide array of functions. Despite their small dimensions and low weight of under 10 kg, the new TransTig 170 and TransTig 210 offer all the important setting options that are otherwise only found in bigger professional TIG devices. The development engineers were determined that the welding system should use the input voltage as effectively as possible, to make the TransTig not only energy efficient but also extremely reliable and productive. The small TIG device offers a duty cycle of 40 percent, while at maximum output, the welder can work continuously for four minutes – a far longer period than with other comparable welding systems.

Furthermore, the Power Factor Correction (PFC) of the TransTig means that it has a high degree of mains voltage tolerance. Even with 30 percent less input voltage, the devices are still able to operate at full power. Furthermore, the PFC function means that the available power from the grid is used as efficiently as possible. By using the Fuse parameter, the welder can adjust the maximum current drawn from the grid and is therefore able to adapt it to the local conditions on-site – such as on construction sites, where many devices are already in operation. This can also make the difference between being able to weld or not in scenarios with long mains leads, poor mains fuse protection or during generator operation.

Large array of functions for easy operation

The compact TransTig devices also boast impressive welding results, which until now were only possible with larger devices. For example, the TransTig features a comprehensive MMA welding mode including CEL mode and various functions for TIG. The spot function (TAC) makes it easier to tack components together, making tacking twice as fast as conventional processes. An additional UpSlope and DownSlope function has been provided to reduce current in order to change a filler rod or to weld over tacked spots. This can be either reduced or even increased in relation or the main current. The gas post-flow time is thereby set manually or automatically according to the welding current being used. Furthermore, the touch high frequency ignition considerably increases user convenience at the start of welding by detecting contact with the workpiece and igniting the high-frequency arc after a pre-defined amount of time at exactly the desired location. This makes it possible to use welding torches without buttons and helps welders with difficult to access interfaces.

Brimming with high-tech features

Despite being packed full of technology, it’s the practical operating concept with simple rotary and push-button and the clear, illuminated function display which make the TransTig stand out. The device is not only lightweight, but also extremely robust, as the plastic housing has been tested for its mechanical load capacity beyond existing standards. Manual welding systems from Fronius are also resistant to spray water, meaning that they are also suitable for use under tough conditions on construction sites or during assembly. Furthermore, the TransTig will automatically switch to standby mode after an adjustable period of time, which reduces energy consumption. The TransTig is therefore the TIG device of choice for portable high-tech use.

Emergency law passed to protect UK steelmaking

<b>(:-))</b> Gareth Stace as director general of trade body UK Steel, is obviously an expert on blast furnace technology & operation. Gareth...