AMETEK Land is helping meet the demand for improved product quality and efficiency in industrial processes with the launch of its new mid-wavelength thermal imager, the MWIR-640 390.

With energy savings, predictive maintenance, and emissions reduction high on the industrial processing agenda, thermal imaging cameras and systems play an important role by providing reliable, robust, and real-time thermal imaging measurements and imagery.

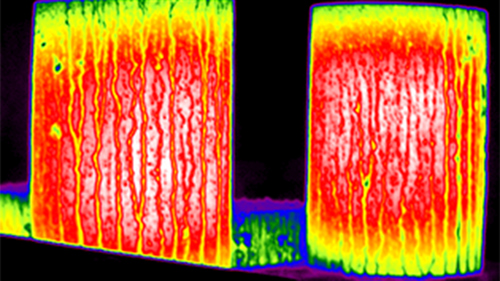

Designed for use in harsh industrial and environmental conditions, the new MWIR-640 390 provides clear images through smoke or particulates in high-temperature processes through its advanced spectral filtering, which shows every surface structure detail in heat treatment applications.

With a pixel resolution of 640 x 480 and high thermal resolution, uniquely clear and detailed thermal images and videos are created at up to a 60 Hz frame rate. This unmatched image quality supports highly accurate process visualization and control.

A wide range of applications from melting to final processing are covered through two temperature measurement ranges – 500 °C to 1800 °C (932 to 3271 °F) and 300 °C to 1200 °C (572 to 2192 °F). This is supported by three lens options offering a choice of optical field of view, complete with motorised focus.

In addition, an integrated web server with multiple I/O options enables the camera to be used autonomously, or integrated easily into new or existing process control systems. Using a standard browser, the web server provides easy camera access, configuration, and remote control. The MWIR-640 390 utilises smart Industry 4.0 capabilities, bi-directional digital interfaces and an on-board I/O for real-time thermal imaging.

Manfred Hayk said: “The new MWIR-640 390 thermal imager is part of LAND’s smart thermal imaging solutions for a range of industrial applications including automation, process control, slag detection, secondary steel-making vessels, and melting operations.

“With decades of experience, our thermal imaging and temperature measurement solutions and software deliver the measurements and data that operators need to meet the demands of high product quality, energy savings, reduced and predictive maintenance and emissions reduction.”

Guest blog: exploring opportunities for hydrogen combustion engines

"We wouldn't need to pillage the environment for the rare metals for batteries, magnets, or catalisers". Batteries don't use rare...