The TPS/i welding platform has a modular design guaranteeing maximum flexibility. The integrated control technology means that welding results are always reproducible and of a high quality.

No matter whether you are dealing with crane booms, large construction machines, trucks, or rail vehicles, long weld seams and thick materials pose a challenge as far as joining technology is concerned. As is the case anywhere with large production quantities, it is important that the production line is always in operation in this context too. System availability—which is dependent on the duty cycle—is of crucial importance here. The technical design of the TPS 600i is fundamentally different from the TPS/i systems in lower power categories. With the more powerful power module, continuous operation is guaranteed for a long time. The TPS 600i achieves a 100 percent duty cycle at up to 500 A during mechanized operation, which is ideal for the combination of long seams and thick materials.

Users really benefit from the high output and long duty cycle of the TPS 600i when working with long weld seams and thick materials.

High Performance Power Module Takes Care of Reserves

The TPS 600i has a maximum welding current output of 600 A and allows for a deposition rate of up to 13 kilograms per hour. The nature of the application determines whether this deposition rate gives rise to an increased seam volume or higher welding speed. If an even greater deposition rate is required, it is possible to combine two of the high performance welding systems for tandem use. In all cases, the high output guarantees short cycle times and high levels of productivity. At the point at which other welding systems would have reached their limit, the TPS 600i still has reserves. Not to mention that the more powerful power module means that the system is not susceptible to high ambient temperatures and it allows for reliable continuous operation and a long service life even when exposed to heat. Additional connections—to allow for the use of more powerful cooling units and an integrated SpeedNet distributor, for example—make it easier to incorporate the welding system into the production environment.

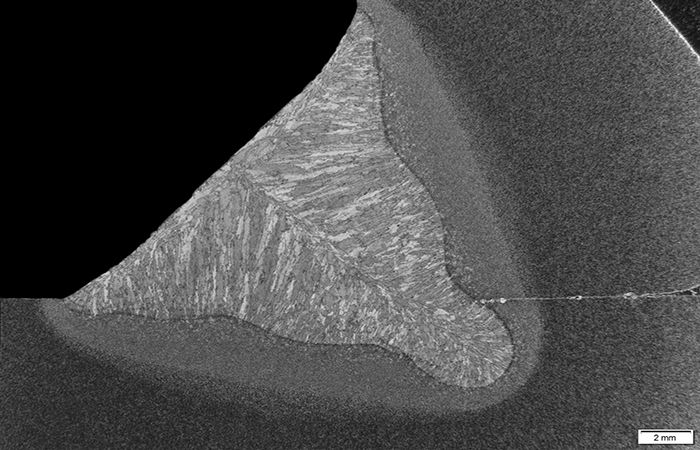

Thanks to the high output with a 100 percent duty cycle, only one weld layer is usually required with the TPS 600i. Weld seams with two weld layers would be the norm with other welding systems.

Material: S235JR; a-dimension: 8 mm; material thickness: 15 mm; welding position: PA; current: 500 A; welding speed: 35 cm/min; deposition rate: 11.4 kg/h; wire diameter: 1.6 mm

Flexibility, Reproducibility, and Support

The TPS/i welding platform technology offers users plenty of benefits: The user can equip their welding system with process variants suited to a wide range of applications at any point. For instance, there is the option of adding LSC for extremely low welding spatter, such as in the case of steel applications, and there are various pulse characteristics too. This means that flexibility and cost efficiency are among the platform technology's benefits. The TPS/i boasts sophisticated control technology that brings about high-quality welding results and precise reproducibility. The system measures the actual data continuously throughout the welding process and control algorithms respond immediately to changes so as to maintain the desired target status. Everyday work is facilitated by the ease with which the TPS/i can be operated. The intuitive interface communicates with the user in 30 different languages, while the touch display is suitable for building sites and designed with the user in mind. Plus, the international Fronius service network guarantees proximity to customers all around the world so that support can be provided in no time. This keeps downtime to a minimum in the event of any problems.

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...