20 Years Later and Our High-Performance Sensors Are Still Being Used in Gemini Telescopes

20 years ago, The Royal Greenwich Observatory in Cambridge approached us to design and build nearly 700 bespoke load cells for two 8.1m diameter telescopes, known as The Gemini Project.

Now 20 years on, these custom-made, high accuracy load cells are still consistently and accurately performing an integral part of the Gemini Telescopes’ control system.

However, technology has changed significantly over 20 years and many of the electronics are now obsolete and unobtainable.

To continue to deliver accurate and detailed astronomical images, we were tasked with the design and manufacture of spare custom load cells to the same dimensional specifications, incorporating up-to-date signal conditioning electronics based on state-of-the-art amplifiers.

These new load cells were able to retro-fit directly into the telescopes’ existing design, while still delivering the same high accuracy and precise outputs to the telescopes’ integral control system.

What is the Gemini Project?

The Gemini Project is an international collaboration to design and construct two identical 8.1 metres optical/infrared telescopes. One is situated in Hawaii and the other in Chile. These huge Gemini Telescopes deliver full coverage over both the Northern and Southern Hemispheres.

The innovative telescopes use 20cm thin meniscus mirrors, which reduce both the weight and production costs, while still enabling them to deform to compensate for gravitational & thermal distortions and wind buffeting.

Each mirror is supported on 120 specially designed control points. Each of these control nodes is made up of 2 load cells mounted on top of one another. The top 500N capacity load cell is used for the fine control of the mirror and is mounted on top of a 2000N load cell.

The force mechanism has been specially designed to ensure the top load cell does not carry the full weight of the mirror but instead passed onto the lower 2000N load cell if the support fails.

In addition, to keep the mirror circular 100x 5000N load cells are equally spaced around the outside rim of the mirror.

These custom designed load cells were specially designed to deliver a high accuracy of 0.02% of full scale, with identical outputs for both the tension and compression control nodes. The internal amplifier and circuitry gave a 5 Volt output linked to a CANbus computer system.

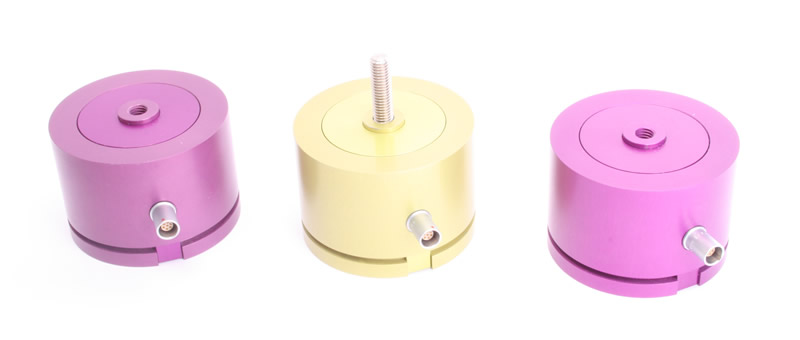

Custom-made load cells

These new custom-built load cells are fitted with state-of-the-art electronics, offering extreme signal stability and precision.

As many of the component parts are now obsolete, it gave us the opportunity to upgrade to newer parts, offering better performance, extreme stability and easier calibration of the load cells.

The newly designed replacement prototype load cells were strain gauged, fitted with the new circuit boards and amplifiers, then fully calibrated for both tension and compression measurement.

They incorporated up-to-date circuitry with the latest internal amplifiers, while still maintaining very high accuracy and outputs to match the existing computer control system. This enabled easy retrofitting of the replacement load cells into the existing control nodes underneath the mirror.

Gemini Telescopes have pictured second-ever interstellar object!

Gemini North Telescope has recently captured a multi-colour image of C/2019 Q4 (Borisov), the second interstellar object ever identified. Read Paul Rincon’s, Science Editor for the BBC news website, report for more details.

Contact Applied Measurements for your own bespoke load cells

We offer a full in-house custom load cell design service, from one-off load cells to high volume.

The Gemini Project has been and still is a fantastic experience and we are proud that our load cells are still being used as an integral part of the mirror’s control system. We hope that we can continue to work closely with the Gemini Team many years into the future.

Why choose Applied Measurements for your application

- ISO 9001:2015 Quality Management Certified

- In-House Sensor Design & Manufacture

- 100+ Years of Transducer Knowledge

- High-Quality Products All Come with a 3 Year Warranty

Radio wave weapon knocks out drone swarms

Probably. A radio-controlled drone cannot be completely shielded to RF, else you´d lose the ability to control it. The fibre optical cable removes...