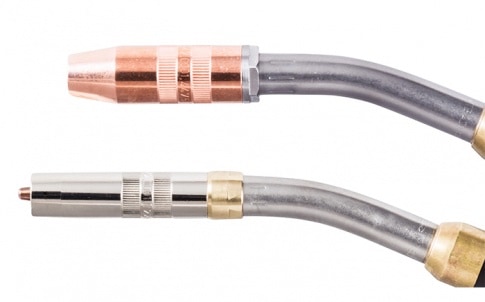

Fronius has developed a new torch body for robotic welding devices: the MTB 350’s gas nozzle has a diameter that is 20 percent smaller than conventional torches, enabling improved access to components.

Owners of the Fronius TPS and TPS/i robotic welding devices can retrofit the new MTB (machine torch body) 350. The gas nozzle’s diameter is now just 20 mm, as opposed to the conventional 25. This means the welding torch can reach the interface more easily, even when working with challenging component geometries.

The torch body is available in various geometries (22°, 36° and 45°). The MTB 350 is also available in the “Asian Style” variant: here, the longer torch body is suited to the typical design of robotic welding torches used in Asia.

Despite the slim gas nozzle, the new torch body enables a high duty cycle at maximum output: at 350 A when using pure CO2, the welding torch achieves a duty cycle of 60 percent, i.e. the arc can operate for 6 minutes out of 10. At 300 A, the torch can weld without interruption. If mixed gas is used, the MTB 350 can achieve a 100 percent duty cycle at 250 A and 60 percent at 300 A.

Radio wave weapon knocks out drone swarms

Probably. A radio-controlled drone cannot be completely shielded to RF, else you´d lose the ability to control it. The fibre optical cable removes...