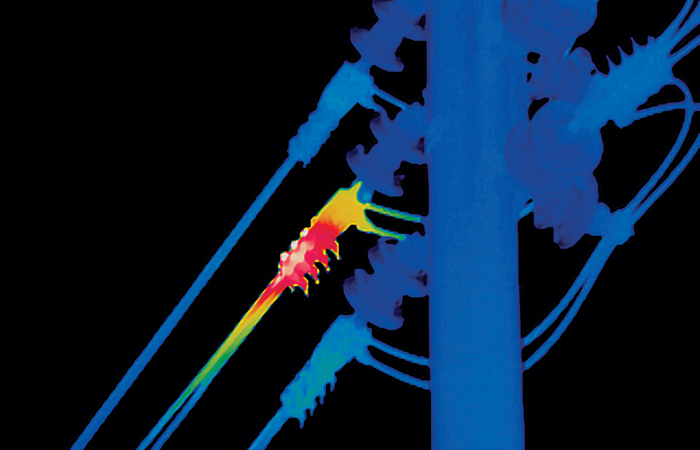

If distribution powerline problems are not caught early, they can lead to a costly outage that disrupts supply to thousands of customers. Regular inspection is essential but there’s a lot the naked eye can miss, especially when it is neither practical nor safe to get close to the components. Isolator or line connector failures, bad or defective connections, or oxidation on connectors can easily go undetected until it’s too late.

In its latest application spotlight for utilities, the thermal imaging company FLIR Systems explains how a high-resolution camera, such as the FLIR T1020 with a 12° lens, gives a full picture of potential problems, quickly and accurately from a safe distance. It also introduces the option of drones with a combination of IR and visual payloads as a great solution when accessibility to pylons or line components is an issue.

Application spotlight link:

https://www.flir.com/instruments/utilities/application-s/

Click here and register to access technical articles and white papers from this company

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...