The development of fiber laser technology is a game-changer for the stainless steel sheet fabrication industry, allowing for faster cutting speeds at half the price of a CO2 laser. Fiber lasers are also more environmentally friendly thanks to their lower energy consumption and allow for accurate laser cutting on a variety of materials.

Fiber lasers and CO2 lasers are two of the main kinds of lasers currently being used in the market for stainless steel cutting. Many factories still use CO2 laser cutting.

This article explains the pros and cons of these two types of technology.

How Does a Fiber Laser Work?

The Fiber laser technique is the most advanced technology on the market. It uses an optical fiber that is often doped with various elements, including neodymium, erbium, thulium, ytterbium and holmium, as well as amplifiers that allow more light to enter. Four-wave mixing and simulated Raman scattering are also used to enhance the process.

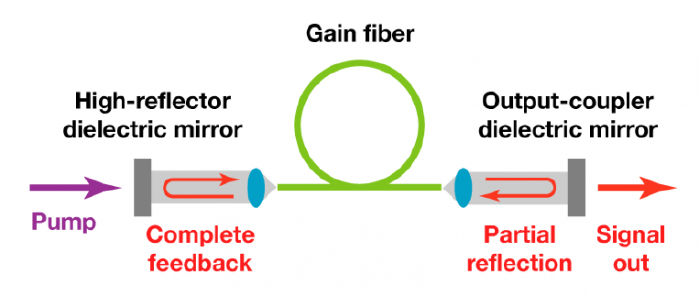

These lasers function by using a fiber that stimulates emissions and amplifies the signals, bouncing them between two reflectors. On one end of the cavity a high reflector with around 100% reflectivity is used to increase signal feedback. At the other end a partial reflector extracts the signal from the cavity while also providing signal feedback.

Figure 1 illustrates how a fiber laser works

The signal output can be in either pulsed or continuous wave. Pulsed fibers are obtained through modulation of the laser cavity loss while the pulse width is determined through the temporal profile from the modulation loss and cavity chromatic dispersion.

How Does a CO2 Laser Work?

CO2 lasers, on the other hand, were one of the first forms of gas laser to be developed. Their main plus points are that they generate more power, enabling the production of a continuous wave. They work by producing an infrared light composed of various wave bands between 9.6μm and 10.6μm.

CO2 lasers use a gas mixture composed mainly of CO2 with smaller amounts of hydrogen, water vapour, oxygen, helium and xenon. The laser is pumped through an electrical gas discharge. The laser power can be generated by exciting the CO2 molecules, although the most efficient technique involves nitrogen in the gas mixture. The nitrogen molecules are often excited through the electrical discharge causing a metastable vibration that is transmitted to the CO2 molecules through collisions.

Adding helium allows for heat dissipation plays a key role in depopulating the lower laser level. Water vapor and nitrogen help by re-oxidizing carbon monoxide formed during the electrical discharge into CO2 .

Figure 2 illustrates how a CO2 laser works

CO2 vs. Fiber Laser: Pros and Cons of Each

Costs and cutting speeds

Fiber lasers are half the price and five times faster than CO2 lasers thanks to their compact design, laser-to-laser configuration use of a beam.

Fiber lasers are also more powerful. A fiber laser of 2kw has a power density that’s five times that of a 4kw CO2 laser. What’s more, their short wavelengths mean laser fibres have a capacity to absorb 2.5 times more waves than CO2 lasers.

More power and a greater capacity for absorption has allowed for a fivefold increase in cutting speeds, especially when working with materials with less than 1/2 inch in thickness.

Fiber lasers can also cut relatively thick materials when using nitrogen in the gas mix so they’re appropriate for those looking for steel plate cutting services. But they really come into their own when cutting materials with a thickness of 1/2 inch. Lower electricity consumption and greater efficiency means costs for operating a laser fiber typically come in at about half that of a CO2 laser.

Figure 4 illustrates the power density and absorption comparisons for fiber lasers and CO2 lasers

The financial benefits of harnessing higher cutting speeds and lower costs are plain to see. A lower cost-per-part can increase profit margin while reducing investment time.

Technological advances such as beam shaping mean more flexibility when cutting thick plates and the use of fiber optics allows for a smaller beam creating a narrow channel to focus on the material. Using oxygen during cutting can widen the channel while keeping power requirements low. A wider beam allows for faster cutting speeds and better edge quality on thicker steel materials.

How we can help you

The benefits of fiber lasers compared to CO2 lasers are multiple. As well as faster cutting speeds and lower operating costs, fiber lasers don’t require the same warm-up times that CO2 lasers do. They’re also easier to maintain since they don’t need alignment, lens cleaning, or bellows checks like CO2 lasers.

At Omnidex Laser, we specialise in providing precision laser cutting services using the latest fiber laser technology, providing both quality and a fast production rate at low prices that can meet most budgets. Our laser cutting services in Scotland use state-of-the-art machines for steel plate cutting and other services, allowing accuracy and speed at competitive prices.

Guest blog: exploring opportunities for hydrogen combustion engines

"We wouldn't need to pillage the environment for the rare metals for batteries, magnets, or catalisers". Batteries don't use rare...