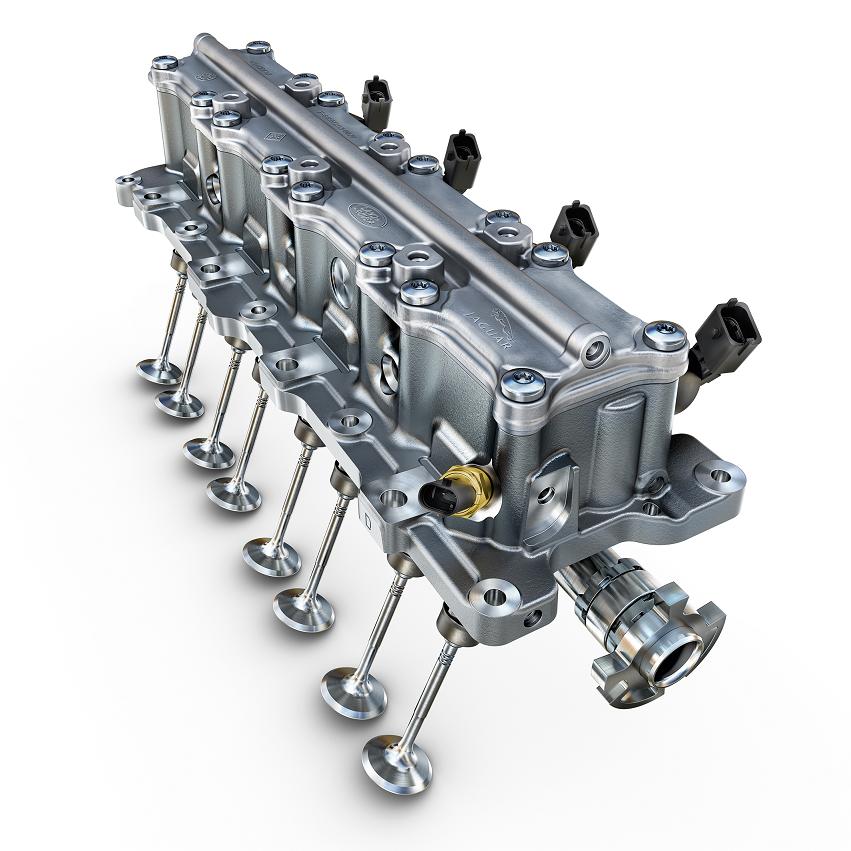

UniAir is a fully variable electrohydraulic valve control system. In doing so, it set standards in environmentally friendly and dynamic engine technology. Schaeffler’s latest UniAir also now allows vehicles in the upper-class automotive market to operate more economically and with lower emissions.

UniAir controls the engine valves based on cycles and offers an extended range of strategic options for matching engine operation to specific situations and requirements. This technology makes it possible to achieve significant reductions in fuel consumption and emissions, as well as a significant improvement in torque curves. By using UniAir, customised operating strategies for modern combustion processes, such as the Miller and Atkinson cycles, can also be realised in accordance with customer requirements.

The latest generation of UniAir technology is also demonstrating its potential. In this specific case – a newly developed four-cylinder gasoline engine series – the UniAir system is combined for the first time with two hydraulic camshaft phasing units in accordance with customer-specific requirements. The additional degree of freedom offered by the system with its optimised mass design means that the engine can operate in an even broader spectrum of the data map with optimum efficiency. This means, for example, that the engine can be switched off in start-stop operation and can be started again at lightening speed, keeping vibrations in both instances to a minimum. Another advantage of the technology is the fast and precise control of the valves to match the relevant cycle. This allows an instant increase in torque without impairing the efficiency of the engine due to the significant retardation of the ignition timing.

Taking steps toward reindustrialisation

Hi Jack, The UK and EU caused their own electricity price problems - for Russia was happy to supply UK after the Ukraine invasion, provided they paid...