Increasingly, the use of reinforced lightweight materials such as honeycomb structures has become a more important element of modern engineering than many metals. The reasons are obvious. Composite materials combine the material properties of multiple material types into one, leading to construction materials that surpass the strength and structural integrity of more traditional materials at about a fifth of the weight.

Of course, the use of honeycomb composite panels is nothing new and one might be forgiven for making a quirky and well-worn reference to ‘rocket science’. Yet it is true that the use of bonded panels in aerospace applications has been with us since at least the late 1930’s followed by NASA picking up the baton decades later, literally taking the possibilities to infinity and beyond.

Joining components to lightweight honeycomb material has traditionally been achieved through the deployment of a variety of fixing elements and techniques such as rivets, adhesives, potted or floating inserts and of course, nuts and bolts. Each of these techniques provides a successful solution in its own right, proffering a differing menu of proven benefits. For example, Load Spreading Rivets (LSR) and Peel Rivets present a fast, single-side solution, easy to deploy. Adhesives, whilst arguably not as fast, present an equally viable alternative driven by the specifics of the application. And where single-sided fastening is not necessarily a prerequisite, then the trusted nut and bolt route can accommodate many different thicknesses of materials in application. Indeed, the latter consideration, material thickness, exemplifies the now vast range of composite materials available to the modern designer, ranging from thermoset materials such as aramid honeycombs, glass-fibre with epoxy or paper honeycomb layers, PUR and PP glass-fibre, some with wood layers and so on. Thicknesses are typically anything up to 30mm.

So now fast-forward to the current market climate and we are without doubt, seeing the popularity of lightweight engineering materials cascade from one sector to the next. Structured foam and honeycomb panels are now widely used in automotive assembly, public transport, emergency vehicle and recreational vehicle construction as well as the previously mentioned aerospace industry. Logic dictates that where ‘lightweighting’ is the goal then any new and proven use of engineering materials will spill over from designer to designer. Goods transportation, the airfreight industry and even office and home furniture manufacturers are showing a keen interest - which means that design engineers will be placing greater performance and significantly, aesthetic demands upon the chosen fixing technique. Looks, durability and strength, load-bearing capacity and problem-free dismantling of attachments are all key issues for design engineers engaged in the aviation industry, vehicle design and the plastics processing industries. So how can the fastening technologies keep up?

Enter stage left a unique collaboration between German fastener manufacturer EJOT based in Bad Berleburg, and automated screw specialists Weber based in Wolfratshausen. The story begins when one of Germany’s leading automotive manufacturers approached EJOT with a ‘Live’ problem. A failing parcel shelf installation was halting production of one of its production-line vehicles. The shelf was manufactured from a PUR fibre-glass and paper honeycomb composite. EJOT’s engineers were able to see the potential for the first serial application of a new fixing component fresh from R&D.

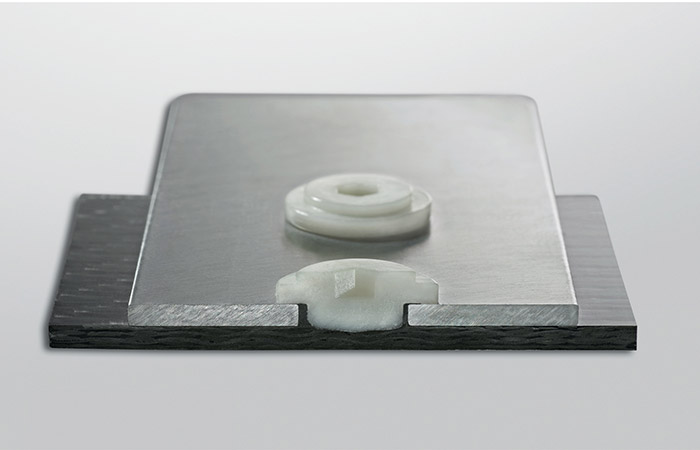

Loosely based on EJOT’s RSD welding boss, TSSD (Thermischer Stoff-Schluss-Dom / thermal adhesive bonding boss) was designed with a 9mm diameter and made from a fibre-glass reinforced thermoplastic polymer. This strength made it possible to apply a specific axial loading to revolution ratio, creating a fast high-strength joint without first creating a pre-hole. Weber’s setting process was critically optimised to achieve this, making it possible to record the setting parameters used. The setting machine was then developed to attach to a small laboratory unit, a portal (x-y) unit or a robot for automatic feeding.

The manufacturer was able to fast-track what has now become the ‘standard’ TSSD into approved production. Such was the impact, that designers immediately reviewed similar assemblies and EJOT’s engineers were tasked with creating variants. A removable battery box cover led to a ball-headed ‘snap-on’ connector moulded in. A male and female hinged connection was developed for the boot space loading floor. An integral drive point addressed the various material combinations of organo sheets - and so on. Currently, three of Germany’s main vehicle manufacturers ‘design-in’ TSSD variants. Pull-out loads for TSSD into the broad standard honeycomb material is typically around 800 N, with loads of up to 1000 N achievable. In organo type materials this rises to as much as 1800 N.

Unsurprisingly, TSSD is now being deployed by aerospace designers, having first met stringent aerospace specification. A modified polyamide, self-locking variant was successfully performance tested for smoke-density, toxicity and flammability (FST). In Korea, a composite design specialist is looking to create ‘flat-pack’ prefabricated homes using variants of the original TSSD design. Even European furniture companies are now using the fastening in wet-area furniture as it moves from wooden products to ranges made from wood-effect honeycomb materials.

EJOT’s UK based application engineers are able to assist and project manage application enquiries from a local perspective. EJOT UK, call 01977 687049 www.ejot.co.uk.

Product Range: https://www.ejot.co.uk/Industrial-Fasteners/Applications/General-Fabrications/Castings/EJOT%C2%AE-EPPsys-TSSD/p/VBT_EPPSYS_TSSD

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...