What is co-solvent cleaning?

Co-solvent cleaning is a powerful and versatile vapour degreasing process that uses a combination of two solvents to clean a variety of substrates. Particularly useful in electronics cleaning, this process is a safe and efficient way to remove organic and mineral residues from solder fluxes and pastes.

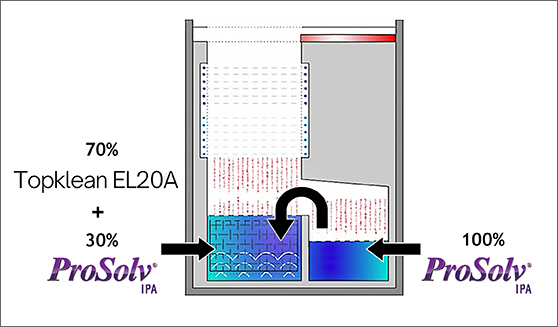

The co-solvent cleaning process uses a mixture of the solvating agent (Topklean EL20A) and a rinsing agent (ProSolv® IPA) in the first cleaning stage, followed by just the rinsing agent in the second stage. Excellent for applications where solubility, material compatibility, sustainability and regulatory compliance are important. Perfect for cleaning circuit boards, semiconductors, avionics,and optical instruments. Co-solvents will help to dissolve contaminants that a single solvent alone may struggle to remove by modifying the overall polarity, viscosity, and evaporation rate of the cleaning solution.

Topklean EL20A is designed to clean solder paste deposits, fluxes and other residues in the production of PCBs, offering excellent cleaning capacity and a very low environmental impact.Designed for use in a co-solvent process to remove residues and leave the surface free of organic and inorganic deposits.

ProSolv® IPA is an environmentally friendly azeotropic solvent cleaner - Ideal for removing adhesives, buffing compounds, drawing oils, fluxes and pastes, greases, hydraulic oils, lapping compounds, resins, inks, silicone oils, and waxes, ensuring thorough and efficient cleaning.

Increasing demand for miniaturized electronic assemblies has led to greater challenges in the parts cleaning process, and manufacturers need to solder with greater precision to avoid problems like corrosion and short circuiting. Co-solvent cleaning enhances the solubility of contaminants, improves efficiency and performance, and helps remove difficult soils which often require high temperatures. Perfect for cleaning small components, high density PCB's or boards populated with very low stand-off components.

A Simple 3-Step Process

Cleaning: Parts are immersed in the boiling sump, which contains a blend of Topklean EL20A and ProSolv® IPA. The low viscosity of the mixture allows for the cleaning of small components and high-density PCB's.

Rinsing: Parts are rinsed in the clean sump of the vapour degreasing tank, which is filled with ProSolv® IPA. With the co-solvent process,

re-deposition of soils is minimized.

Final stage: Components are moved into the vapour zone for drying, without the need for expensive high-temperature ovens. The entire process is done automatically and under a sealed lid. EnviroTech Europe also supplies vapour degreasing equipment like the Solvac S2 which is perfect for co-solvent cleaning.

|

CO-SOLVENT CLEANER BENEFITS |

INDUSTRY APPLICATIONS |

|

Enhanced solubility |

Aerospace and avionics |

Co-solvents Product Brochure

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/co-solvents for information

Supplied and supported by

EnviroTech Europe Ltd, Steward House, 14 Commercial Way, Woking, Surrey GU21 6ET, United Kingdom

Tel +44 (0) 20 8281 6370 | www.envirotech-europe.com | contact@envirotech-europe.com

Company registered in England and Wales No. 4170693

Invinity to build 20MWh flow battery in UK

Redux flow cells have had nowhere near the R+D effort compared to Lithium ion. They certainly have the potential (pun not intended) for longer...