When the shafts in pumps, ventilators, compressors and gearboxes are not precisely aligned with one another, they run out of round. The resulting imbalance increases the temperature in couplings, bearings, greases and motors. The system uses more energy and undergoes increased rapid wear. Shafts may even break, resulting in unplanned, total machine and system outages. For this reason, shafts should always be correctly aligned after each assembly operation as well as during maintenance work.

Simple, precise and cost-effective

A new system for the alignment of rotating shafts based on innovative single laser technology can be found in one of Schaeffler's latest products, the LASER-EQUILING2. In contrast to the conventional double laser system, which requires the mutual alignment of two laser/sensor units, the single laser technology uses just one laser/ sensor unit and a reflector. As the single laser is only aligned with the reflector, the system is quickly operational. Delivering precise measurement results and is also an attractive option in terms of cost-efficiency.

Increased energy efficiency saves money

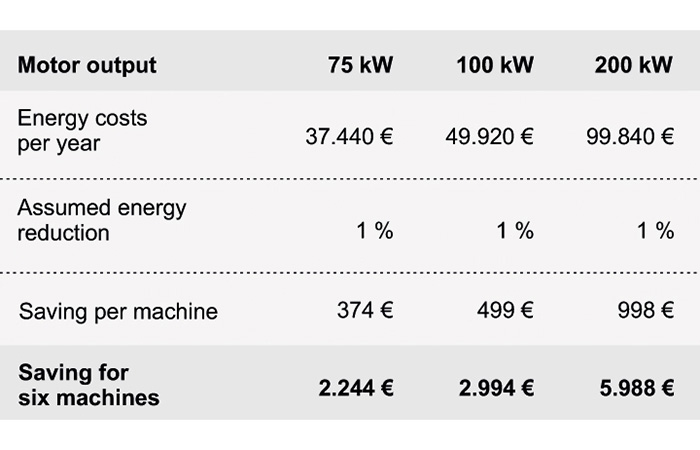

The following calculation gives an example of the often underestimated savings potential that precisely aligned shafts can offer. The calculation is based on an 8-hour operating day, an electricity price of € 0.24 per kWh and an assumed energy reduction of one percent.

With the LASER-EQUILIGN2, Schaeffler is offering an economical and user-friendly system for precise shaft alignment. The increased reliability of your machines makes for lower total cost of ownership (TCO), which every machine operator strives for.

For more information visit: https://medias.schaeffler.co.uk/en/mounting-and-alignment/alignment-tools/equilign

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...