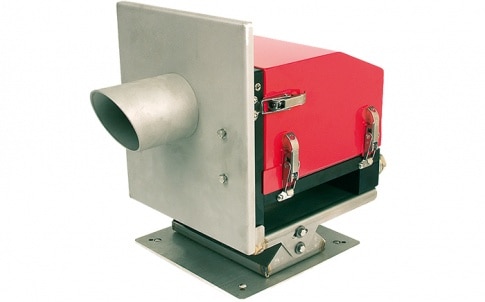

AMETEK Land has developed an innovative new pyrometer for accurately measuring the temperature of galvannealed and galvanized steel strip.

The SPOT GS steel application pyrometer provides continuous and accurate temperature measurement of coated steel strip during the galvanneal reaction. This enables steel producers to accurately measure the temperature in a galvanneal furnace, allowing it to run at optimum throughput rates in order to ensure consistent, high-quality, premium-coated steel demanded by the automotive industry.

“The SPOT GS is a revolutionary new pyrometer, designed for even greater accuracy and convenience in galvannealed and galvanized steel strip applications. With specialised pre-set algorithms, the SPOT GS can provide both accurate digital temperature readings for galvannealed or galvanized surfaces and liquid surfaces seen on the exit from the zinc pot,” comments Chris Leonard, Director of Development & Product Management for AMETEK Land.

“We are confident that we have developed a temperature measurement solution that will optimise efficiency and achieve cost savings for steel producers, who can benefit from its accurate digital temperature readings, ease of use and robust design.”

SPOT GS enables automated furnace management to provide close control of the reaction and position of the reaction zone, delivering tighter control of product quality. By maintaining control of the reaction zone, the steel application pyrometer accommodates rapid changes of line speed and furnace power with variations to substrate or coating weight. This allows for furnace optimisation, reducing heating costs, maximising throughput and avoiding excessive over-reaction and powdering or flaking of the coating during subsequent forming operations.

The innovative new SPOT GS application pyrometer can be integrated with furnace controls, PLCs and control software. By integrating directly, furnaces can run reliably and consistently and produce the highest quality products, with minimal scrap. The SPOT GS has additional inputs and outputs including emissivity out and LED switching, which are available as analogue/digital control I/O as well as over Ethernet.

Combining Ethernet, Modbus TCP, video, analogue and alarm outputs within one device, SPOT makes all these conveniently available to the operator. Pyrometer readings and configuration settings are available on the rear display and remotely via a web browser or through dedicated SPOT software.

SPOT GS is available with the free to download SPOTViewer software, which allows configuration and display and logging of data. In addition, AMETEK Land offers a range of mountings and accessories that are compatible with all SPOT pyrometers, which allows for great flexibility and ease of use.

All AMETEK Land SPOT pyrometers are designed for high accuracy, reliability, simple installation, configuration, and flexible digital communications. The SPOT GS was specifically developed in close collaboration with industry-leading steel producers and plant control system engineers. The SPOT GS pyrometer is set to lead the way in improving steel strip throughput via quality and energy efficiency.

Microplastics evading capture in wastewater treatment

Can anyone provide a link to a credible peer-reviewed study demonstrating toxicity from microplastics? This report uses words like ´potential´ and...