The importance of combatting climate change is accelerating. The Paris Agreement 2050 highlights the need for steep emissions cuts within the decade to keep global warming to no more than 1.5°C and safeguard a livable climate (UN Net-zero Coalition). To accomplish this, heavy industrial manufacturers are quickly setting up operations with large investments, and tech start-ups are creating novel solutions. Despite this, global targets are not being met.

The most efficient, effective, scalable method to help lower CO2 emissions is the use of direct air capture (DAC). DAC is a technology that enables the separation of CO2 from air to create the products the economy needs. DAC also enables sequestration - the ability to store CO2 for constructive purposes - turning it from a threat to an opportunity.

Removing carbon from the atmosphere requires a system of filters, heat exchangers, condensers, gas separators, and compressors. These complex parts require geometries that are well-suited to additive manufacturing (AM). AM is more efficient and potentially more cost-effective than traditional fabrication methods and delivers substantive performance and economic benefits such as design optimisation for energy efficiency, design freedom, performance, scalability, and supply chain efficiencies. AM satisfies the production requirements of such reactors and can enable applications that address a variety of needs for carbon capture.

Microturbine Equipment

Microturbines present an opportunity to provide high-pressure, high-efficiency gas and fluid conveyance, in a small form factor, with a minimal energy/carbon footprint. High performance, reliable air compression, and system pressure stability are critical to the function of carbon capture systems. As these systems trend towards more commercial units, it’s even more critical to make use of novel, compact turbine technology to enable high efficiency, small footprint operation.

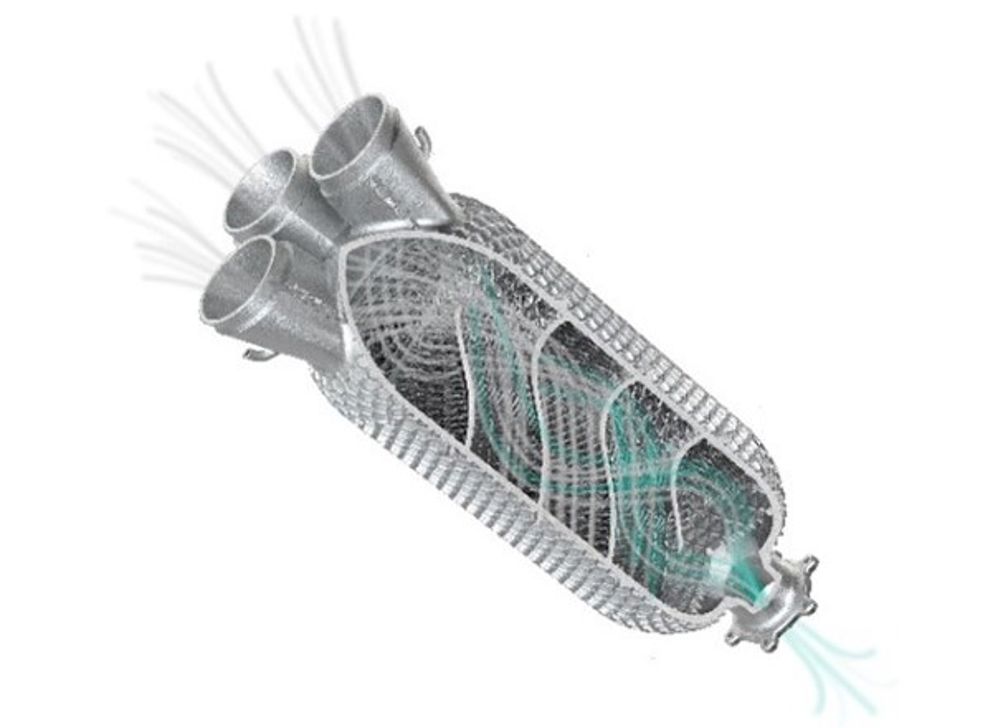

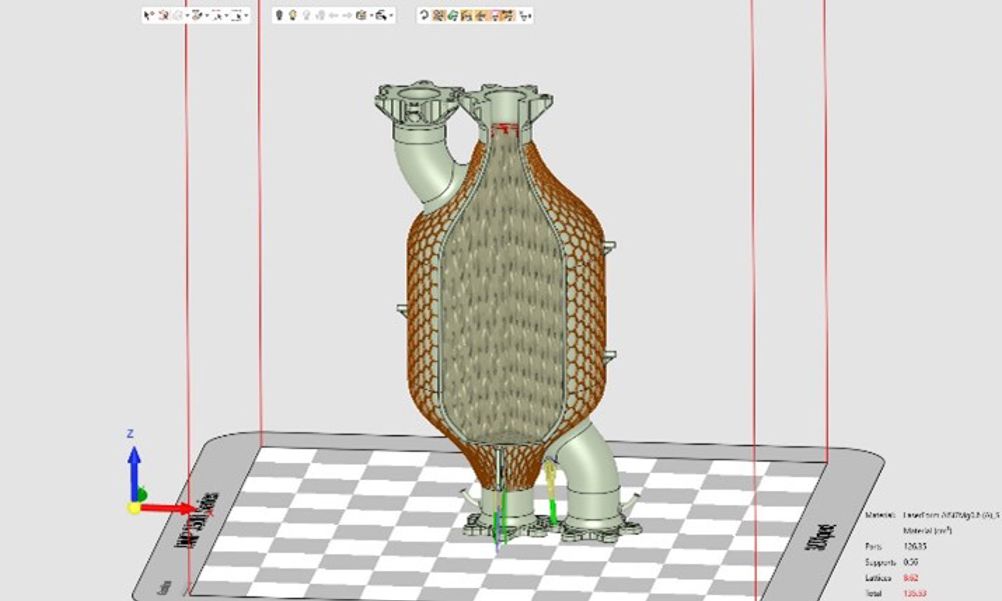

Mechanical Filters

A critical component of carbon capture is “catching” the carbon with a structured mechanical filter, typically coated with an Amine that attracts carbon. Air is drawn into the system through the first stage which is the “direct air contact” stage. Filter efficiency can be maximised by filter structures that allow for maximum contact between incoming air and the filter surface. AM enables the function-first design of such filters which can induce high levels of turbulence and mixing as well as high surface area for maximum air contact.

Heat Exchangers

Carbon captured in the direct air contact stage must be evacuated from mechanical filters into downstream refinement stages. This is frequently done via pressurised steam liberating the carbon from the filter. Heat exchangers can be applied to eliminate surplus heat from the steam generation process, and more commonly downstream reducing the temperature of the carbon-rich steam which exits the filter stage. Furthermore, novel heat exchange strategies are coupled with downstream distillation and refinement steps to keep the process at a stable temperature to sustain chemical reaction and produce output carbon product.

Diffuser Plates

Diffuser plates are similar to a garden hose spray nozzle which takes a chaotic fluid flow and produces a structured and even flow. Liquid diffuser plates are important components of process stacks to ensure uniform flow and treatment of carbon-rich fluid as it flows through the process. Borrowing concepts from aerospace fuel nozzle design, and semiconductor capital equipment showerhead applications, diffusor plates can be additively manufactured 20X faster than with machining alone.

Chillers and Distillers

The carbon-rich product exiting the filter stage is considered “dirty” and requires further processing to be usable. The most valuable, promising carbon capture systems have some level of integrated dirty carbon product post-processing to yield clean usable carbon product and safe water-based byproduct.

Refinement columns which can include distillers with integrated chilling, and heat exchangers are relatively complex to assemble traditionally. AM enables extensive part consolidation and monolithic design, and thus significant consolidation and streamlining of the supply chain. It also enables function-first, highly efficient design which can accelerate the refinement stage and provide even more output in a smaller form factor.

Manifolds

Manifold applications in carbon capture range from chemistry conveyance into process chambers, to the efficient distribution of coolant to active cooling components such as heat exchangers, and gas distribution applications. What makes these components challenging to produce is not the requirements for chemical resistance or aerospace-grade special materials, but the need for balanced pressure across many branching lines, and delivery of fluids through a process chamber. Efficient one-to-many branching with even fluid flow combined with space and assembly restrictions is a geometry problem that AM is uniquely positioned to address.

The possibility of a future when we can breathe easier

DAC and refinement is a critical technology for correcting atmospheric carbon levels, and AM is currently enabling significant efficiency advances in the technology. With further adoption of advanced manufacturing technology and design tools, we believe we can rest easier knowing that the climate may still be comfortable and liveable for future generations.

Scott Green, principal solutions leader, 3D Systems

Radio wave weapon knocks out drone swarms

Probably. A radio-controlled drone cannot be completely shielded to RF, else you´d lose the ability to control it. The fibre optical cable removes...