Due to a constant track record of less-than-optimal project performance, including schedule and cost overruns, many are on a quest for better predictability. On top of this, there is the need to reduce carbon footprint and get to revenue faster, which directly impacts how we design, engineer and deliver projects.

Attempts to address project shortfalls using various means such as lean methods, contracting strategies and team building have not been enough to deliver the necessary improvement. To augment current practices, we need to shift attention to focus on the how: how we produce engineering, how we control what needs to happen and how we constantly improve.

Let’s start by examining the common and inherent challenges in design and engineering production, which we see repeatedly on all kinds of projects around the globe.

- Engineering is performed by resources that are not necessarily co-located, but rather do work from multiple locations.

- Hundreds to thousands of engineering deliverables per project need to be produced within a given time window, each by a certain date (not always the same for each deliverable).

- Deliverables are driven by technical, regulatory, and internal governance requirements.

- Some deliverables are produced by a single engineering discipline, while others may require the involvement of multiple disciplines including reviews and approvals by one or more parties.

- Although a single engineer may understand the end-to-end process to produce a single-discipline deliverable, the more production processes are multi-discipline, nobody seems to have a clear picture of the overall production process for those types of deliverables (the exact ‘how to’).

- Technical disciplines share capacity across multiple projects or sub-projects within a single project, while priorities vary within and across projects as well. This creates tension between those responsible for managing the projects and those leading each discipline – we call this “the fight for capacity”.

- Engineers tend to use their “list of deliverables” and associated target dates (e.g., registers) as references for their work, not schedules. Managers use schedules to track progress against the established baseline. Schedules always seem to be out of date.

- 3D models are standard practice to produce, integrate and standardise asset design. However, the use of digital prototyping and focus on product standardisation does not necessarily guarantee process standardisation.

- Given the digital and cyclic nature of the work, it is very difficult to know physical progress – what work is actually done.

What can be done to reliably deliver engineering within a dynamic and complex environment like this?

Look at the production system.

Some organisations have successfully dealt with these complexities by focusing on how the work gets done through the underlying production system. With this framework in mind, we recommend projects take these four actions.

- Model and optimise engineering production systems

Create digital models of engineering production systems using leading-edge technology underpinned with Operations Science. The opportunity is to better understand how the production processes should behave including the effect of shared capacity in throughput and cycle times, identify optimal levels of work-in-process, while identifying bottlenecks and how they shift position over time.

- Standardise engineering production

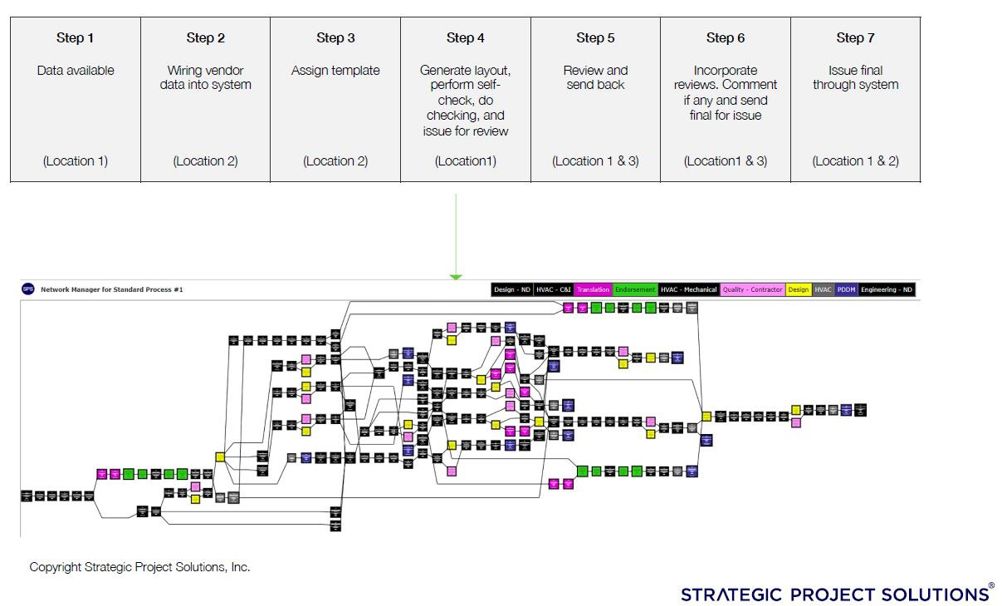

Standardise engineering production workflows. Teams may be blind to the fact that they execute work through a limited number of processes (standard processes) that repeat for many deliverables. Standardising work contributes to reducing (not eliminating) variability, hence, reducing engineering cycle times. To illustrate, the following example (Figure 1) contrasts a classic progress monitoring perspective with seven steps (project administration) with the reality of the work (execution-level standard process across multiple disciplines) for the development of ~40,000 loop diagrams – every single loop diagram needs to go through the detailed production process depicted below. Situations like this give managers “the illusion of being in control”, while moving them away from becoming more predictable.

- Control work-in-process, manage capacity and reduce variability

Put in place a systematic way of controlling what work, and how much of it, is released for execution, the dynamic allocation of capacity to that work, and to identify sources of variability. Allocation of capacity is not the same as creating a manpower histogram using master schedules as the means to determine the demand for labour resources, but rather refers to the dynamic allocation of specific engineers to the work in execution cycles including the ability to plan and re-plan work because variability will always exist.

- Focus on production-based continuous improvement

Understand how the engineering production system is behaving now and compare it to what it should be using production-based indicators such as throughput, work-in-process, cycle times, capacity utilisation as well as sources of variability.

If you are responsible for project design and engineering or directly involved in the creation of engineering deliverables, what do you plan to do to improve performance in such a dynamic and complex environment? More of the same, getting the same less-than-optimal results? Or are you starting to look toward the production side of projects?

Roberto J. Arbulu, an instructor at the Project Production Institute and VP of SPS Technical Services

Emergency law passed to protect UK steelmaking

<b>(:-))</b> Gareth Stace as director general of trade body UK Steel, is obviously an expert on blast furnace technology & operation. Gareth...