Leveraging over 50 years of expertise and advanced laser technology, Wärtsilä enhances the performance, longevity, and environmental sustainability of white metal applications.

A Leap Forward in Bearing Technology

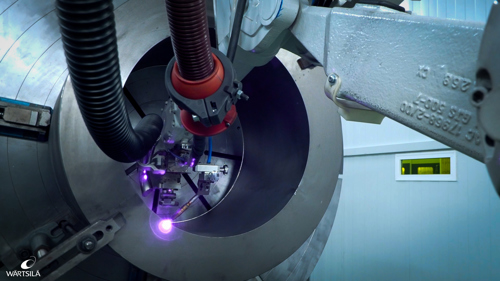

Wärtsilä’s 100Bond® technology represents a substantial upgrade over traditional casting methods. Utilizing a highly automated laser deposition process, the technology delivers remarkable precision and consistency. This advancement addresses several inherent limitations of conventional techniques, such as dependency on operator experience, hazardous material handling, and inefficiency in material utilization.

The traditional method involves warming white metal to 500°C, which is both time-consuming and environmentally taxing. Material utilization rates hover around 25%, with up to 60% needing recycling, and the process involves significant risks, including exposure to smoke, cooling water, and hazardous acids. In contrast, Wärtsilä’s automated laser process eliminates these hazards, ensuring faster processing and enhanced quality, free of inner defects and suitable for mass production and complex geometries.

Exceptional Performance and Durability

The refined microstructure achieved through Wärtsilä’s laser technology results in exceptional bonding strength, enhancing both the mechanical and tribological properties of white metal applications. This improvement translates into significantly longer lifespans for components, especially under high-load and heavy-vibration conditions. For instance, the white metal application on a tilting pad the size of a coffee cup can be completed in just two minutes using this innovative method.

The technical specifications of the 100Bond® technology reveal improvements of up to 40% in mechanical bonding and fatigue resistance compared to regular casting procedures. This leap in performance is crucial for industries that demand high reliability and minimal downtime, such as marine, oil and gas, nuclear power, and mining.

According to Rafael López, Business Development Manager, “100Bond® technology is revolutionizing the babbitting industry and setting a new standard.”

Environmental and Operational Benefits

Wärtsilä’s 100Bond® technology is not just about performance; it’s also about sustainability. The environmentally friendly nature of the process minimizes hazardous impacts, aligning with global environmental regulations and contributing to a greener planet. The rapid service capabilities of Wärtsilä ensure that the improved results are delivered swiftly, minimizing operational downtime and enhancing efficiency across various applications. "100Bond® reduces 90% of CO2 emissions in bearing manufacturing and promotes the retrofit of parts, increasing the circular use of components," explains Beatriz García, Bearing Centre Manager.

This technology is particularly beneficial for applications such as steam turbines, compressors, hydropower, gearboxes, stone crushers, grinders, and mills. By improving the performance and lifetime of these critical components, Wärtsilä helps industries achieve greater operational reliability and cost-effectiveness.

Highlighting Expertise: The Bearing Centre Team

The success of Wärtsilä’s 100Bond® technology is driven by the expertise and dedication of the team at the Bearing Centre. At the forefront is Beatriz García, an accomplished industrial engineer and the Bearing Centre Manager. With extensive experience in white metal technology, Beatriz leads a team of skilled professionals who are committed to delivering innovative solutions and maintaining the highest standards of quality.

“The Bearing Centre exemplifies excellence in engineering,” says Jesús Fernández, Director of SLS Spain and China. “Our commitment to pushing the boundaries of technology ensures that Wärtsilä remains at the forefront of industrial solutions.”

ASME Turbo Expo 2024: Showcasing Innovation

This week, the Wärtsilä Bearing Centre team attended the prestigious ASME Turbo Expo in London. This event provides an excellent platform for showcasing Wärtsilä’s innovative 100Bond® technology and networking with industry leaders and peers. The team's participation underscores Wärtsilä's commitment to advancing engineering excellence and staying at the forefront of technological innovation. Their next stop will be Enlit Europe in Milan (22-24 October 2024).

For more information on Wärtsilä’s 100Bond® white metal technology and their comprehensive range of services, visit Wärtsila Bearing Centre.

Arriva makes £300m tri-mode train order with Hitachi Rail

This development shows up the lack of a comprehensive nationwide network of electrified lines for passenger services and freight The glacial speed of...