A recent study by the US Centers for Disease Control found that 98 per cent of people tested had detectable levels of PFAS (Per- and polyfluoroalkyl substances) in their bloodstream.

A new filtration material developed by researchers at MIT could provide a nature-based solution to this contamination issue. The material can remove a variety of these persistent chemicals as well as heavy metals. Furthermore, the material’s antimicrobial properties can help keep the filters from fouling.

The findings are described in ACS Nano, in a paper by MIT postdoc Yilin Zhang, professor of civil and environmental engineering; Benedetto Marelli, Associate Professor of Civil and Environmental Engineering, and four others from MIT.

PFAS are present in products such as cosmetics, food packaging, water-resistant clothing, firefighting foams, and antistick coating for kitchenware. A recent study identified 57,000 sites contaminated by these chemicals in the US alone. The US Environmental Protection Agency has estimated that PFAS remediation will cost $1.5bn per year, in order to meet new regulations that call for limiting the compound to less than seven parts per trillion in drinking water.

According to Zhang, contamination by PFAS and similar compounds is a ‘very big deal’ with current solutions only partially resolving the problem.

“That’s why we came up with this protein and cellulose-based, fully natural solution,” he said in a statement.

The initial technology that made the filtration material possible was developed to make a labelling system to counter the spread of counterfeit seeds, which are often of inferior quality. Marelli’s team devised a way of processing silk proteins into uniform nanoscale crystals, or nanofibrils, through an environmentally benign, water-based drop-casting method at room temperature.

Zhang suggested that their new nanofibrillar material might be effective at filtering contaminants, but initial attempts with the silk nanofibrils alone did not work. The team then added cellulose, which is abundantly available and can be obtained from agricultural wood pulp waste.

Related content

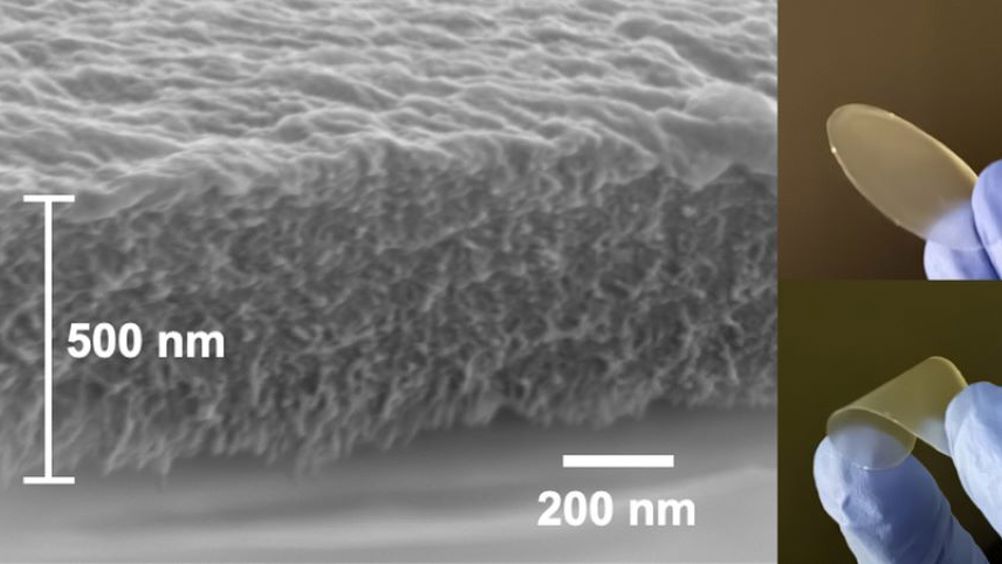

The researchers used a self-assembly method in which the silk fibroin protein is suspended in water and then templated into nanofibrils by inserting ‘seeds’ of cellulose nanocrystals. This causes the previously disordered silk molecules to line up together along the seeds, forming the basis of a hybrid material with distinct new properties.

By integrating cellulose into the silk-based fibrils that could be formed into a thin membrane, and then tuning the electrical charge of the cellulose, the researchers produced a material that was highly effective at removing contaminants in lab tests.

The electrical charge of the cellulose also gave it strong antimicrobial properties, which should ‘greatly reduce’ fouling.

“These materials can really compete with the current standard materials in water filtration when it comes to extracting metal ions and these emerging contaminants, and they can also outperform some of them currently,” Marelli said.

In lab tests, the materials were able to extract orders of magnitude more of the contaminants from water than activated carbon or granular activated carbon.

Marelli said the new work serves as a proof of principle, but the team plans to continue working on improving the material, particularly in terms of durability and availability of source materials.

Initially, the material would likely be used as a point-of-use filter attached to a kitchen tap. Eventually, it could be scaled up to provide filtration for municipal water supplies.

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...