Self-charging cell directly converts and stores energy

Researchers at the Georgia Institute of Technology (GATECH) have developed a self-charging power cell that directly converts mechanical energy to chemical energy, storing the power until it is released as electrical current.

They claim that, by eliminating the need to convert mechanical energy to electrical energy for charging a battery, the new hybrid generator storage cell utilises mechanical energy more efficiently than systems using separate generators and batteries.

Central to the system is a piezoelectric membrane that drives lithium ions from one side of the cell to the other when the membrane is deformed by mechanical stress.

According to a statement, the lithium ions driven through the polarised membrane by the piezoelectric potential are directly stored as chemical energy using an electrochemical process.

By harnessing a compressive force, the power cell generates enough current to power a small calculator.

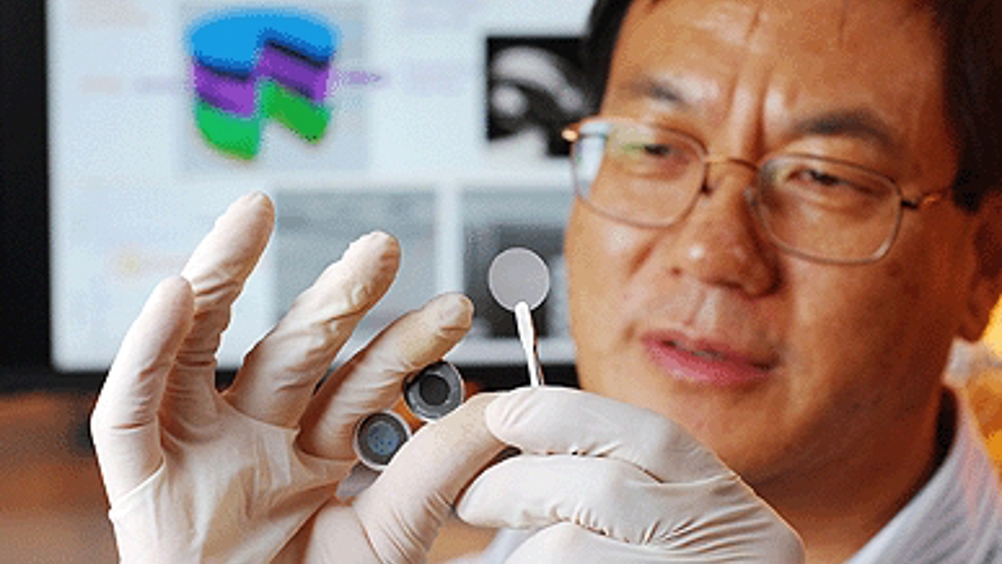

A hybrid power cell the size of a conventional coin battery can power small electronic devices — and could have military applications for soldiers who might one day recharge battery-powered equipment as they walk.

‘People are accustomed to considering electrical generation and storage as two separate operations done in two separate units,’ said Zhong Lin Wang, a Regents professor in the School of Materials Science and Engineering at GATECH. ‘We have put them together in a single hybrid unit to create a self-charging power cell, demonstrating a new technique for charge conversion and storage in one integrated unit.’

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...