Their new diamond transistor is claimed to overcome the limitations of previous developments in the technology to create a device much closer to being of practical use across a range of industries that rely on high power systems.

The team has found a new way to use diamond as the basis of a transistor that remains switched off by default - a development that ensures safety in devices that carry a large amount of electrical current when switched on.

Diamond has a wide band gap and can handle much higher voltages than silicon - the material most transistors are made from - before electrically breaking down. In power electronic applications, transistors made from materials such as diamond can withstand significantly higher voltages and deliver higher power than Si transistors.

The team said its diamond transistor could find applications in sectors where largely voltages are required and efficiency is highly-valued, like power grids or electric vehicles.

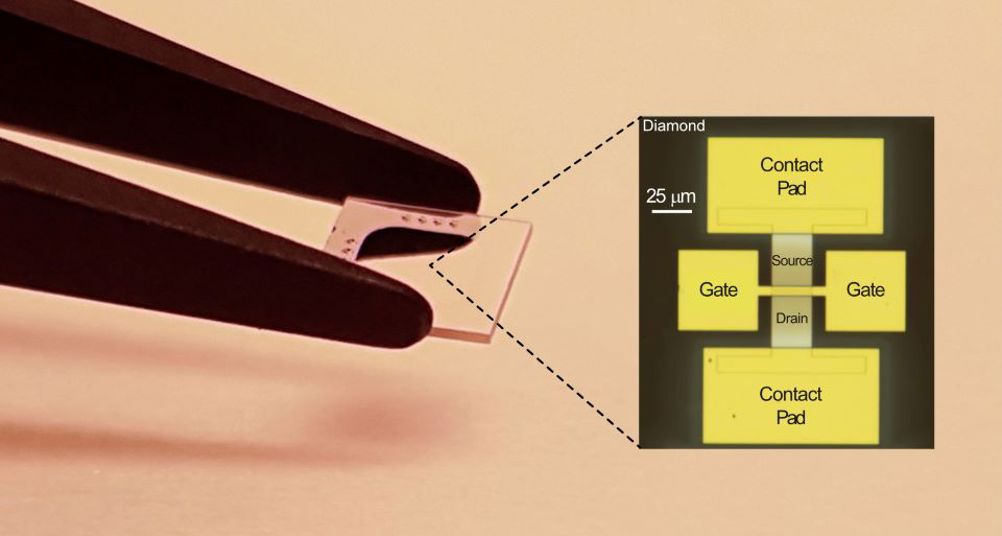

Professor David Moran, of Glasgow University’s James Watt School of Engineering, led the research team with partners from RMIT University in Australia and Princeton University in the USA. Their research is published in Advanced Electronic Materials.

In a statement, Prof Moran said: “Transistors are essentially switches that control electrical current. Devices like computers or smartphones use billions of tiny silicon-based transistors which draw small amounts of power, but power electronics use much fewer switches at significantly higher power levels.

“The challenge for power electronics is that the design of the switch needs to be capable of staying firmly switched off when it’s not in use to ensure it meets safety standards, but it must also deliver very high power when turned on.

“Previous state-of the-art diamond transistors have generally been good at one at the expense of the other. What we’ve been able to do is engineer a diamond transistor which is good at both, which is a significant development.”

At Glasgow University’s James Watt Nanofabrication Centre, the team used surface chemistry techniques to improve the performance of diamond, coating it in hydrogen atoms followed by layers of aluminium oxide.

Their diamond transistor requires six volts to switch on, more than twice the voltage compared to previous diamond transistors, while still delivering high current when activated.

They also improved how efficiently charge moves through the device, achieving twice the performance compared to traditional diamond transistors.

When switched off, the device's resistance is high enough that it measured below the noise floor of the team’s equipment in the lab, meaning almost zero current leaks through when it's supposed to be off.

Prof Moran added: “These are really encouraging results, which bring diamond transistors much closer to achieving their potential than ever before. The production cost for diamond is surprisingly low for a material that many people associate with luxury goods, but there are still challenges to be addressed before diamond transistors are ready to be scaled up by the manufacturing industry.”

Guest blog: exploring opportunities for hydrogen combustion engines

"We wouldn't need to pillage the environment for the rare metals for batteries, magnets, or catalisers". Batteries don't use rare...