The US Navy is partnering with academia to develop a ‘smart’ prosthetic leg equipped with specially designed sensors to monitor walking gait and alert users to wear and tear.

Joseph Xu)

Traditional leg prosthetics depend on soft limb tissue to function and can be painful to wear, resulting in awkward walking motion and possible skin infection.

To overcome these limitations, the US Office of Naval Research (ONR) is partnering with Walter Reed National Military Medical Center, the Naval Research Laboratory and several universities to develop MOIP (Monitoring OsseoIntegrated Prostheses).

“MOIP not only can improve quality of life, but also usher in the next generation of prosthetic limbs,” said Dr Liming Salvino, a program officer in ONR’s Warfighter Performance Department.

According to ONR, leg prosthetics most commonly fit amputees’ residual limbs via a socket that encloses the limb. Because the socket exerts pressure on the limb’s soft tissue, pain and chafing, sores and blisters, and infection can occur. Amputees often have their socket prosthetics adjusted, which is inconvenient and costly. Consequently, many amputees give up prosthetics for wheelchairs.

MOIP is said to use an alternative limb type called an osseointegrated prosthetic—which includes a titanium fixture surgically implanted into the thigh bone, (femur). Bone grows, or osseointegrates, at the connection point with the implant, leaving only a small metallic connector protruding from the remaining leg. An accompanying artificial limb then can be attached or detached. The same procedure can be performed for upper limbs.

The advantages of osseointegrated prosthetics are said to include less pain, a fluid walking motion and a more stable, better-fitting limb. But because metal sticks out of the residual limb, infection is a constant risk. To address this issue, MOIP will focus on infection detection, eradication and prevention by developing electrochemical sense-and-respond approaches and “smart” skin technologies.

This includes a bio-compatible sensor array embedded within an amputee’s residual limb coupled with additional sensors on the osseointegrated prosthetic itself. The first technology of its kind, the array tracks changes in body temperature and pH balance, indicators of possible infection. It also monitors how well the bone and prosthetic limb fuse together and heal, allowing doctors to dramatically speed the recuperation process of warfighters.

Over time, the sensors evaluate the prosthetic’s strength, how much stress a user’s body places on it, and any changes to movement and walking gait.

“One game-changing application of this technology would be as a tool to inform doctors when prosthetics can be safely loaded after surgery, leading to more accurate determination of when patients are ready for physical therapy after receiving a new prosthetic,” said Dr. Jerome Lynch, a University of Michigan engineering professor who is overseeing the sensor array’s development. “Right now, doctors study X-ray images of a limb when making that determination.

“Because the sensors transmit information wirelessly, doctors also could potentially study patient data via a handheld reader,” said Lynch. “Think of it as an extremely specialized Fitbit. This could dramatically improve the recovery and long-term quality of life for patients.”

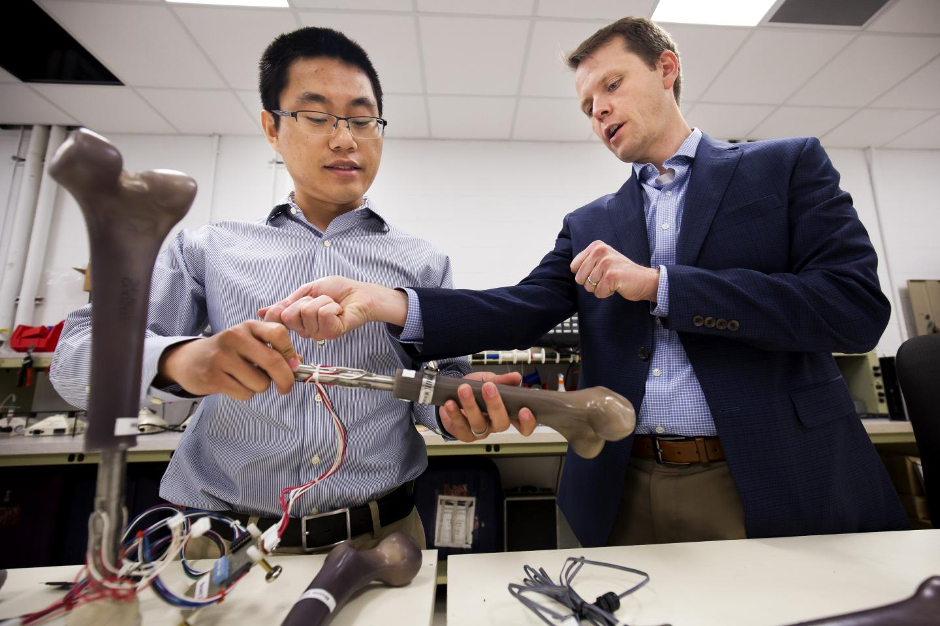

Lynch and his team successfully created a MOIP sensor array prototype using osseointegrated prosthetics and synthetic bone models manufactured at the University of Michigan. While this prototype was successful in laboratory tests, they hope to have a new, improved model ready for clinical trials early next year.

https://www.theengineer.co.uk/inprog/

IET sounds warning on AI doll trend

I agree that we need to reduce cooling water demand for servers. And yes, generative AI consumes a large amount. But what about BitCoins? Their...