Introducing the T-SMILS Laser Heating System

Hamamatsu’s corporate philosophy emphasises the advancement of photonics through extensive research and yields products that are regarded as state-of-the-art. All products are designed to cover the entire optical spectrum and provide solutions for a wide variety of applications including analytical, consumer, industrial, and medical instrumentation. However, few people recognise that as a company Hamamatsu also offer a range of laser products.

This range of semiconductor laser applied products can be used in a number of applications, from R&D to full-scale production. Recently, Hamamatsu introduced the T-SMILS Laser Heating system (L15570 series, see Fig.1 below) as a new addition to the SPOLD product line, ideally suited to applications requiring critical temperature control. This product represents an upgrade to our previous laser heating technology, using a much faster sensing regime which allows you not only to monitor, but to use temperature instead of power as the main metric for laser processing.

Product functionality

The basic function of the T-SMILS system is to heat the materials to be processed with the aid of laser energy, thereby initiating the desired thermal processing. Diode lasers are used in these products, which mostly operate with a wavelength of 940nm and an output power of up to 360W. The laser diodes are used to produce a wide range of laser outputs. Spot sizes from 0.1 to 6.4mm in diameter and line optics are available to adapt the laser properties if required. Hamamatsu uses a special process to optimize the shape of the laser beam and achieve what is known as a 'top hat beam profile'. The resulting energy distribution allows an optimal and homogeneous heat input to the objects to be processed.

CLICK HERE TO LEARN MORE ABOUT HAMAMATSU'S LASER HEATING PRODUCT RANGE

However, the unique feature is the integrated process monitoring. The T-SMILS can measure absolute temperature, whereas most temperature monitoring systems use relative temperature measurement, making it possible to monitor the process temperature in real time during treatment by the laser. Therefore, it allows us to control the process to a higher extent than previous laser systems. The current application focus for this system includes plastics welding, sintering, curing and soldering, with the confidence to resolve the inconsistencies that have been faced by the plastics industry for many years.

For example, when two plastics are welded together, the temperatures must be kept exactly within very narrow limits in order to achieve the desired strength of the joint. If the traversing speed or the laser power is not set optimally, the welding process will not achieve the desired result. Therefore, using this new temperature functionality, variances between plastics welding batches will no longer be an issue as the temperature at the melt-point is controlled automatically and continually by this new sensing technology.

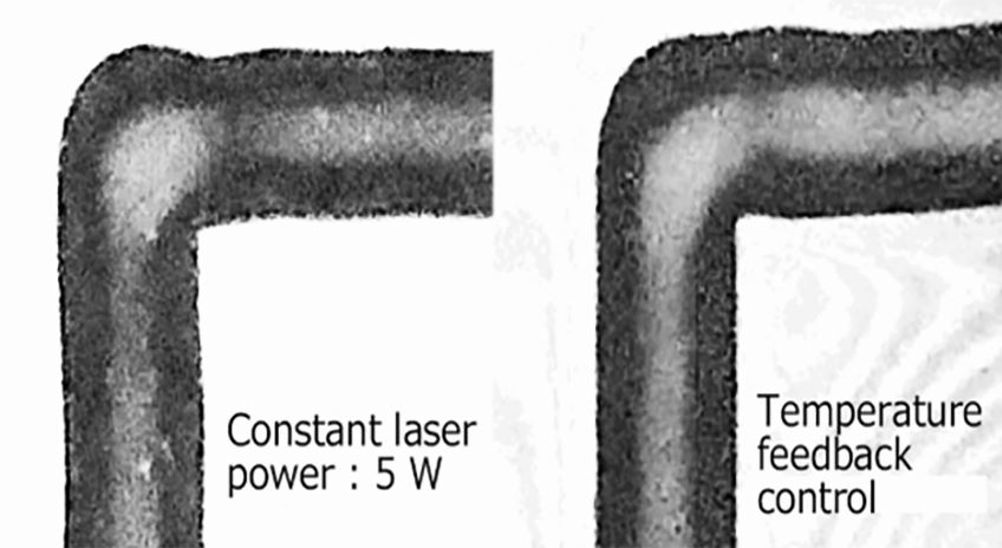

In Fig.2 above, you can see the difference that temperature feedback control makes to a laser weld. On the left-hand image, we can see a microscope image of a laser weld at constant power through a corner. The laser power is unevenly distributed, causing over-melt and under-melt at different points. However, the image on the right-hand shows a consistent weld using temperature feedback control.

Comprehensive service

Hamamatsu provides a comprehensive service and with our experience, we make a significant contribution to ensuring that users can implement their systems as quickly as possible. As part of this service, we support our customers in the evaluation. We can advise them which spot sizes and laser heads are best suited for the respective application, among other things. The wide range of options for spot sizes and laser heads makes our laser product range very flexible as they can be tailored precisely to customer requirements.

"With integrated real-time temperature monitoring, Hamamatsu can provide the user with completely new possibilities for laser processing.

In combination with our experience in this field and our laser laboratories based in Germany and Japan, we offer our customers added value in the evaluation and implementation of their solutions."

Contact information

Hamamatsu Photonics UK Limited

10 Tewin Rd, Welwyn Garden City AL7 1BW

Tel: +01707 294888

Email: info@hamamatsu.co.uk

Web: www.hamamatsu.com

PMI falls as manufacturers feel the squeeze

17 months or two and a half years - which is it?