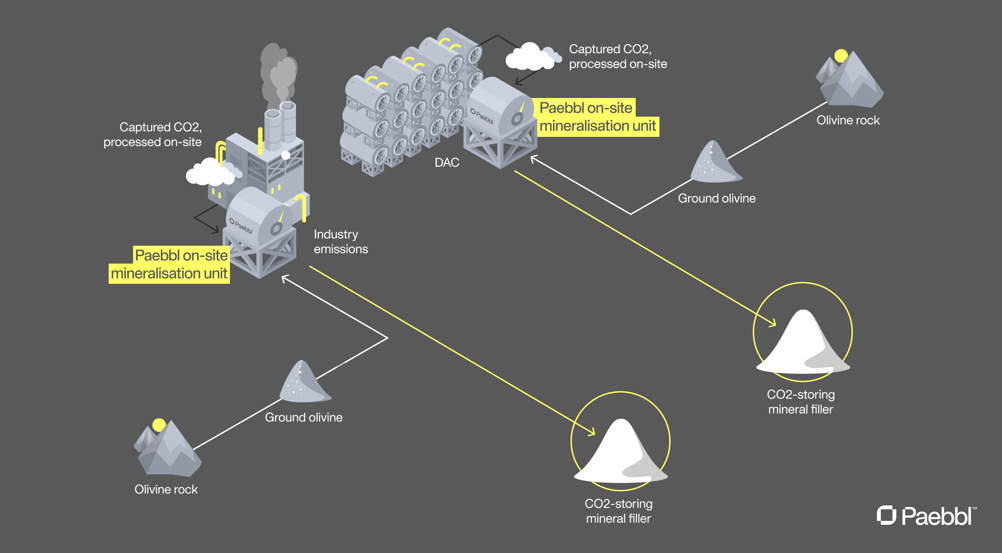

Using a low-energy patented process, Paebbl’s reactors convert CO2 into CO3, adding water and ground silicate rocks to produce a solid carbonate-based material. For every tonne of CO2 stored, the process generates up to two-and-half tonnes of material. According to the company, the silica-enriched mineral can be used as an inert industrial filler or as an ingredient in building materials, reducing the CO2 footprint of concrete by as much as 70 per cent.

Related content

Having only recently taken the technology beyond the lab, Paebbl has now commissioned a new 500L batch production unit called ‘Obelix’. The company claims that Obelix has scaled Paebbl’s CO2 processing capacity 100x in less than six months, with the reactor capable of delivering up to 100 tonnes of carbon-storing materials annually.

“With over two decades of research going into our technology, Obelix is a clear statement of intent that we are committed to meeting the strong industry demand for our products,” said Andreas Saari, co-founder and co-CEO at Paebbl.

“Obelix is an important milestone that will allow us to cater to the wider industry, and the next step on our path to decarbonise the built environment - which currently accounts for 38 per cent of global carbon emissions. Our current mission is to scale-up our technology as fast as possible so that we can meet the needs of the market and the planet.”

Founded in 2021, Paebbl currently has about 20 employees across Rotterdam, Helsinki, and Stockholm. The company says it expects to start shipping samples produced by Obelix to early adopter customers across the Benelux and Nordic regions from Q1 2024. Its next scale-up step will be a ten-fold continuously operating pilot plant, due to come online by Q4 2024. Paebbl claims that plant will produce CO2-negative materials and help de-risk the technology for full commercialisation.

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...