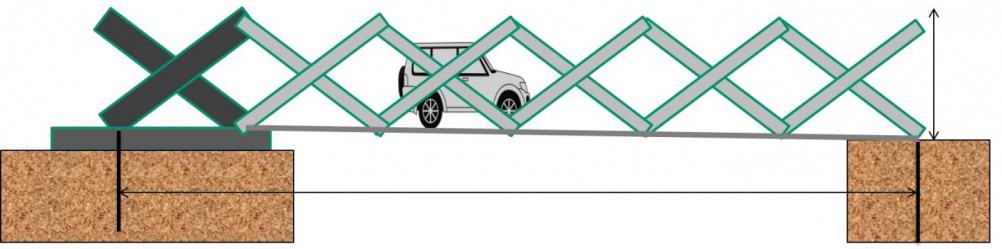

The Mobile Bridge Version 4.0 (MB4.0) can fit in a car trailer, and unfolds in a scissor-like fashion to span small rivers and ravines. Its first construction test took place last month over the Hongo River in Fukuyama City, near Hiroshima in southwest Japan.

“From this test of a new bridge concept, the next generation of bridge technology starts on a new stage in the field of bridge engineering,” said Dr Ario, who is assistant professor at the Institute of Engineering, Hiroshima University.

“It is possible to use a real deployable and smart bridge with a scissor-type bridge system using this structural theory.”

From arrival on site, MB4.0 takes approximately one hour to deploy, with the actual extension time taking just five minutes. It is claimed that the patented scissor mechanism outperforms the older block assembly method of construction, making MB4.0 “the world’s lightest, fastest, largest, strongest and lightest expanding temporary bridge.”

No foundation construction or crane operations are required to deploy the bridge, and it is hoped that its speed and flexibility could lead to faster relief reaching areas in need following natural disasters such as earthquakes, floods, tsunamis and landslides.

Dr Ario believes MB4.0 could also have other applications, such as providing structural support to existing bridges in need of repair, or as an alternative crossing where a bridge is closed for maintenance.

“I will further promote the development and evolution of MB4.0 in the future.,” he said. “Making MB stronger, longer, lighter, more compact, and quicker to set up will promote the development of infrastructure construction technology in general.”

Emergency law passed to protect UK steelmaking

<b>(:-))</b> Gareth Stace as director general of trade body UK Steel, is obviously an expert on blast furnace technology & operation. Gareth...