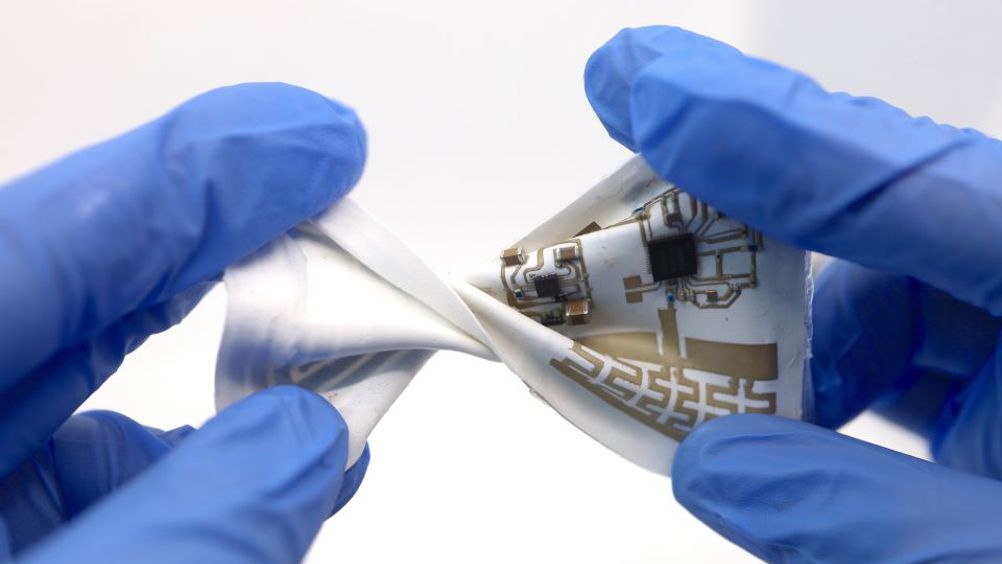

New material enables stretchable wearable devices

Next-generation wearable devices could be imbued with continuous, consistent wireless and battery-free functionality following the development of a material that moves like skin while maintaining signal strength in electronics.

An international team of researchers from Rice University, Texas and Hanyang University, South Korea developed the material by embedding clusters of highly dielectric ceramic nanoparticles into an elastic polymer. Their findings are published in Nature.

The material was reverse engineered to mimic skin elasticity and motion types, and also to adjust its dielectric properties to counter the disruptive effects of motion on interfacing electronics, minimise energy loss and dissipate heat.

In a statement, Raudel Avila, assistant professor of mechanical engineering at Rice and a lead author of the study, said: “Our team was able to combine simulations and experiments to understand how to design a material that can seamlessly deform like skin and change the way electrical charges distribute inside it when it is stretched so as to stabilise radio-frequency communication. In a way, we are carefully engineering an electrical response to a mechanical event.”

Avila explained that two antennas communicating with each other do so at a given frequency.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...