Lactate is an important marker of fitness and fatigue and by enabling continuous monitoring during training and sports the mouthguard system is expected to give athletes and their coaches unique access to key performance information for real-time optimisation.

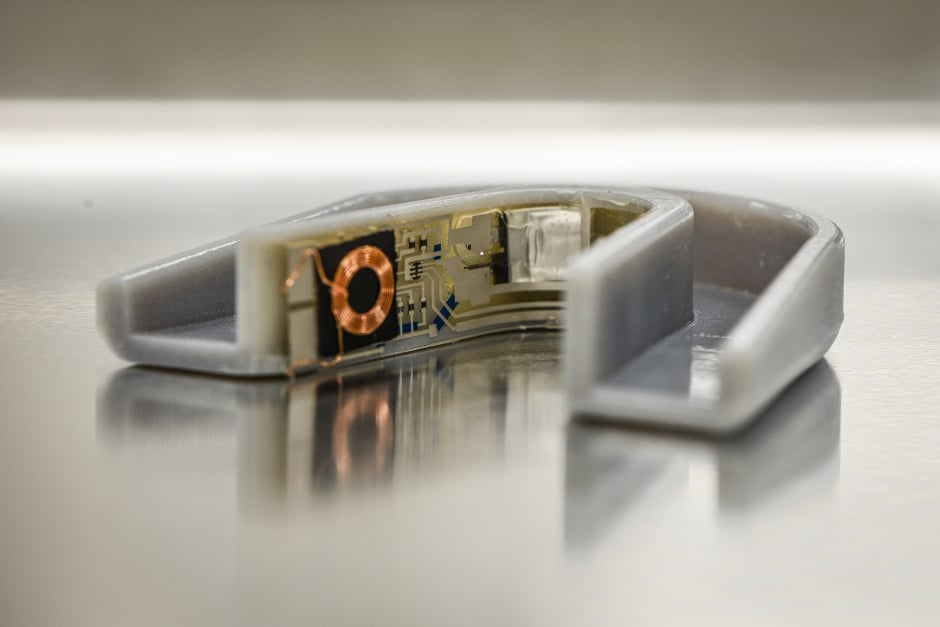

The wirelessly rechargeable electrochemical sensor – which uses Bluetooth Low Energy for data communication - is fabricated on a flexible plastic foil, then mounted on the mouthguard.

The mouthguard system is being developed by PARC, a subsidiary of Xerox Corporation, and the University of California San Diego. It has received funding from NextFlex, a consortium of public and private entities formed to advance the development of flexible-hybrid electronics (FHE).

“In the semi-automated FHE fabrication process, the first interconnect is screen-printed on a flexible polymer substrate in a three-step process,” explained Dr David Schwartz, project lead and manager of Energy Devices and Systems at PARC. “The primary set of conductive traces are printed, a dielectric protective layer is printed in areas where two traces will cross over, [and] the conductive crossovers are printed.

“Next, anisotropic conductive paste [ACP] is extrusion printed in the areas where component pads will be placed,” he added via email. “A custom pick-and-place instrument is then used to place the discrete electronic components on the substrate. Heat and pressure are applied to bond them and electrically connect them via the ACP.”

Schwartz added that the primary challenges in this system related to making it work with a diverse set of components.

“We surveyed numerous anisotropic conductive adhesives, both pastes and films, and fine-tuned the heat and pressure application to enable bonding both of large and small components.”

The sensor electrodes are subject to biofouling as they must be in contact saliva, but they are protected with an anti-biofouling polymer material to mitigate this. Lactate levels are determined via enzyme-based chronoamperometry and the system’s wireless charging uses the Qi standard to charge an onboard Li-ion battery.

“Current consumption for a single Tx/Rx event is 15.4mA for 1.00msec,” said Schwartz. “What’s more important, I think, is the total use time per charge. That depends on the sample rate, etc. With one sample/transmission per second, the system should be able to operate for one week on a single charge.”

The eventual aim is for the electronics to be attached to or embedded in a mouth guard but ultimately, said Schwartz, it might be a general label that is compatible with a generic mouth guard.

“Initially, however, it is more likely to be a specialty product,” he said.

Radio wave weapon knocks out drone swarms

I hope they have assessed how easy it is to shield a drone against the attack. Hopefully the shielding would add too much weight.