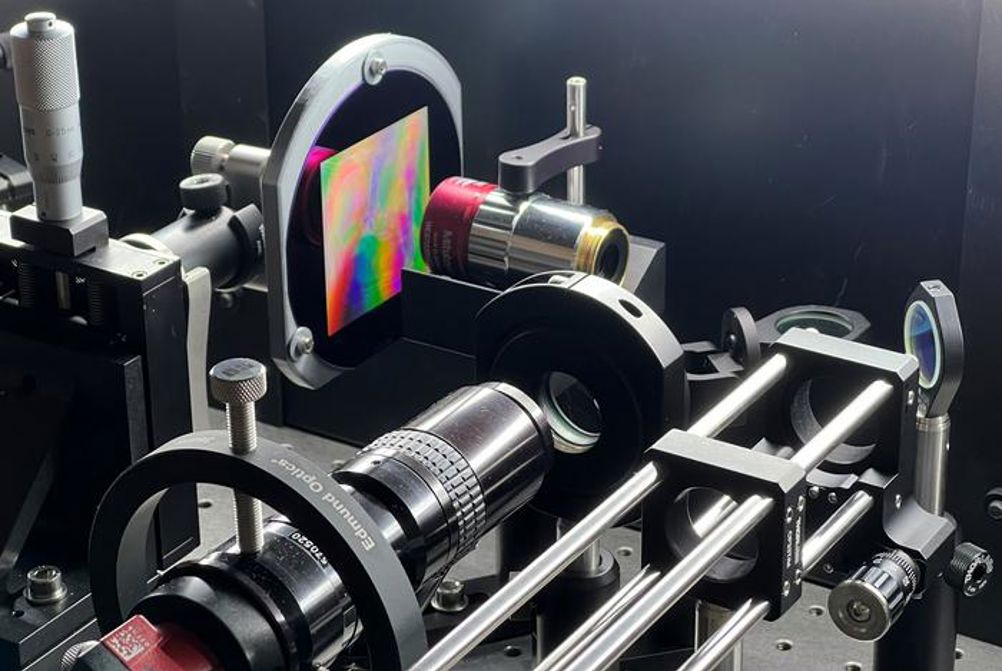

Developed by engineers at Brown University and TU Delft, the silicon nitride lightsail measures just 60mm x 60mm, but with a thickness of just 200 nanometres. Its surface is intricately patterned with billions of nanoscale holes, helping to reduce weight and increase reflectivity. Scaled up, the material could be driven by a high power laser on Earth, rapidly accelerating to speeds that enabled a new generation of spacecraft to reach our nearest stars in journeys lasting decades rather than millennia.

Related content

According to the researchers, fabrication took just a day and is thousands of times less expensive than previous methods used to create similar materials. It’s claimed the membrane has the highest aspect ratio of any lightsail created to date. The process is published in Nature Communications.

“This work was a joint effort between theorists at Brown University and experimentalists at TU Delft making it possible to design, fabricate and test a highly reflective lightsail with the largest aspect ratio recorded to date,” said Miguel Bessa, an associate professor in Brown’s School of Engineering who co-led the research with Richard Norte, an associate professor at TU Delft.

“The experimental breakthrough of Richard’s team proves their fabrication process is scalable to the dimensions needed for interstellar travel and can be done in a cost-effective manner. Simultaneously, my team is very enthusiastic to see the essential role of our latest optimisation method guided by machine learning in solving such an interesting and difficult engineering problem.”

Optimising the design involved formulating a pattern of billions of nanoscale holes across the material’s surface, with diameters smaller than the wavelength of light. The team developed a new artificial intelligence technique to calculate the shape and placement of the holes for increased reflectivity and decreased weight. According to Bessa, the new method could have applications far beyond this niche use case.

“The new machine learning and optimisation techniques we used here are very general,” he said.

“We could use them to create lots of different things for different purposes. This is really just the beginning. We might be on the verge of solving engineering problems that have remained unsolvable up to now.”

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...