To recap, Prosperity Partnerships are five-year projects to investigate topics of national and global importance. They are co-funded by government and industry, with the research areas identified by business and undertaken in collaboration with universities.

EPSRC is investing £20.4m in the scheme, while industry partners are putting in £16.8m and universities are contributing £4.9m. Partners from industry include Akzo Nobel, AstraZeneca, Oxford Photovoltaics, Google, Rolls-Royce, Tata Steel and Weir Group.

The first round of projects - covering topics including electromagnetic and acoustic materials, photonics, offshore wind energy – were announced in 2017 and are now said to be attracting additional foreign investment.

The seven new projects will look at areas including a new virtual factory approach to steel production, new materials for solar panels, sustainable coatings and paints, and bio catalysts for the production of medicines. They represent a way of stimulating and directing basic research towards industry requirements, which hasn’t always proven successful, prompting The Engineer to ask if this approach will be more successful than others, and whether the right subjects are being tackled.

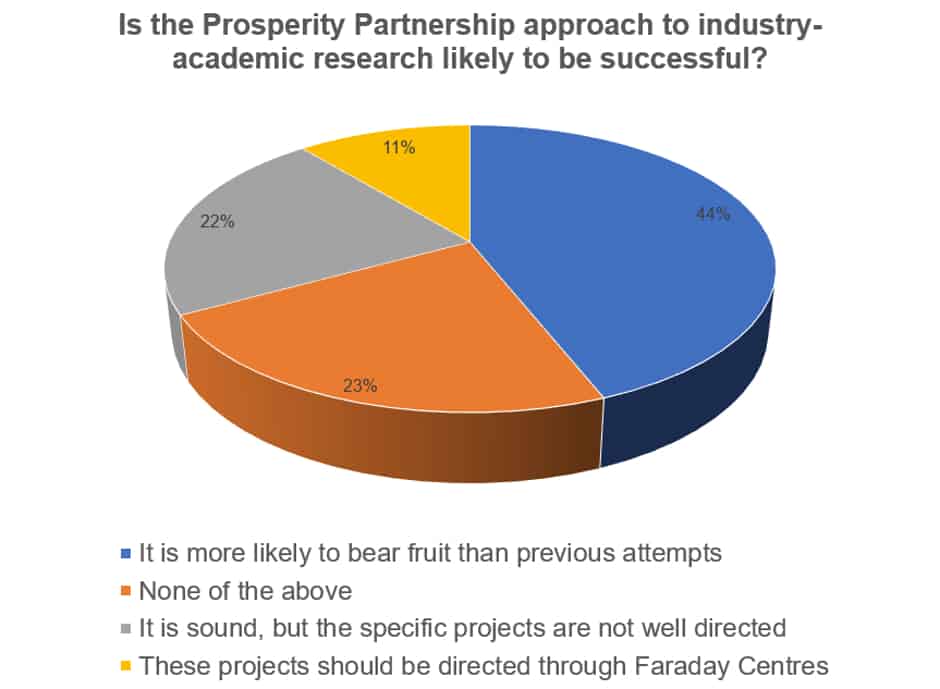

Under half of respondents – 44 per cent – agreed that the new partnerships will provide tangible outcomes, followed by 22 per cent who thought the partnerships sound in principle but not in direction. The remaining 34 per cent of vote saw 11 per cent agreeing that the new projects should be directed through Faraday Centres, and just under a quarter (23 per cent) opted for the none of the above option, including Another Steve who said: “This sounds like a sell-out of R&D to the sharks of the commercial world – beware. Surely the clue is in the name, Prosperity, Partnership Initiative = PPI.”

Julian Spence added: “Perhaps if there were some partnership that was establishing why innovative (small or start-ups) firms find it difficult to innovate AND to follow up by further innovation on success that would be better; it would set a foundation for creating partnerships that were truly innovative – but I suspect that it would involve business resourcers (finance & academic managers) moving away from their beloved business plans and poor understanding of managing risks (managing not avoiding).”

Finally, Rich used comments to say: “The AMRC in Sheffield is a great example of university – industry collaboration and it needs to be done more because there is clearly a gap between academic and industry in the UK. The gap might be due to an attitude problem, it is much easier for universities to earn money by the “bums on seats” policy for accepting students (and their bloated tuition fees) and companies put short term shareholder gain above long term competitive advantage.”

What do you think? Let us know using comments below. Comments are moderated. The Engineer’s policy on guidelines for comments can be found here.

The seven new Prosperity Partnerships:

Developing a new virtual factory approach to steel production, involving computational techniques and scale-up activities, aimed at reducing screening times for new materials by a factor of 100 led by Tata Steel in partnership with Swansea University

New materials for solar panels, focusing on perovskites, led by Oxford PV in partnership with Oxford University

Sustainable coatings and paints, using studies of coatings failure combined with a machine learning approach to designing protective coatings and nanocomposites, led by Akzo Nobel in partnership with the University of Manchester

Bio catalysts for production of medicines, and developing both new complex therapeutic molecules and new manufacturing technologies, led by AstraZeneca with Prozomix and in partnership with Manchester University

Quantum simulation and software development to harness the power of quantum computing, combining developments in quantum processor hardware with quantum algorithm development, led by Google in partnership with University College London

Hi-fidelity virtual 3D simulation of a complete gas turbine engine during operation, led by Rolls-Royce in partnership with Edinburgh University

New oil and gas well stimulation technology, using numerical modelling, sensing and electronic control to enable a targeted pulsed stimulation process that could improve exploitation of subsurface energy sources in a socially responsible way, led by Weir Group in partnership with Strathclyde University

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...