As well as driving energy production, hydrocarbons are widely used as a chemical feedstock for a huge range of manufactured goods including electronics, clothing and household chemicals such as detergents. Finding alternatives to this fossil carbon is essential if manufacturing is to become sustainable.

Related content

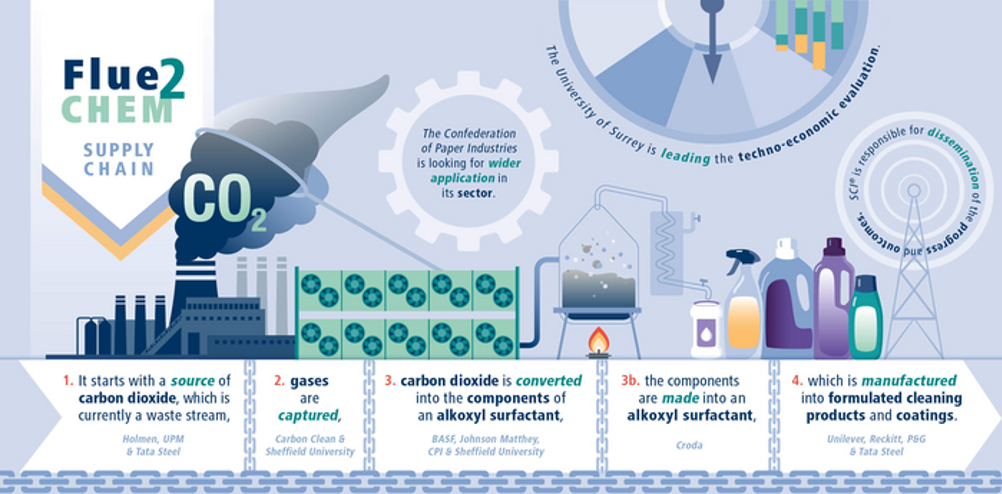

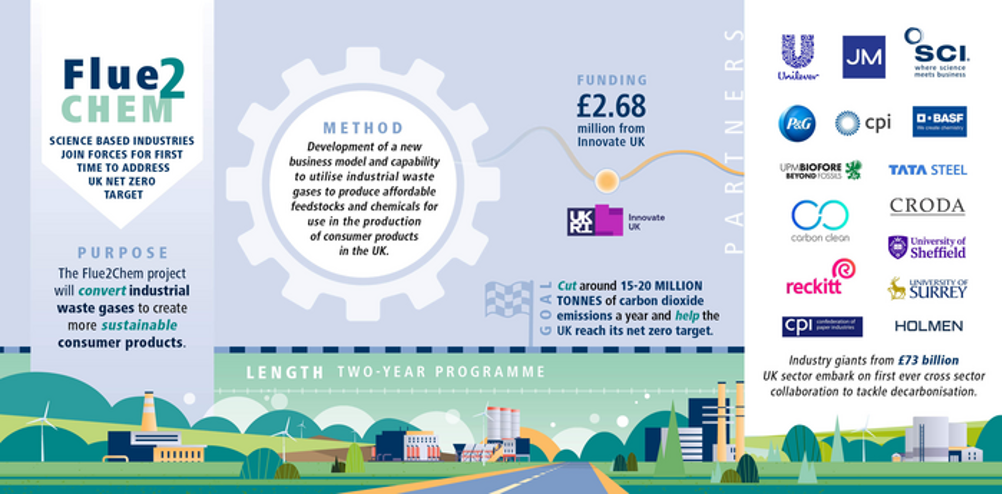

Backed by £2.68m from Innovate UK, Flue2Chem will seek to capture industrial waste gases and convert them into alkoxyl surfactants, a chemical building block that form the basis of many household chemicals and coatings. The two-year programme – which features 15 academic and industrial partners - is aiming to develop a new value chain that could ultimately help the UK cut 15–20 million tonnes of carbon dioxide emissions a year.

“This is a game-changing opportunity to accelerate action and rewire the chemicals value chain to be less reliant on fossil fuels,” said project lead Ian Howell, Unilever’s Home Care Science and Technology R&D director. “It’s a bold ambition and one that, at Unilever, we have been publicly calling for action on over the last two years.

“No single company can do this alone and so to have the power of 15 manufacturers and academics marks a significant step forward not only for the UK, but globally too.”

A report published by the Nova Institute and Unilever in April 2021 estimated that demand for fossil-derived chemicals will more than double by 2050. As a result, renewable carbon production will need to increase by a factor of 15 if it is to successfully phase out the use of fossil carbon in consumer products.

Unilever has already taken the first steps in proving the concept, releasing detergents and cleaning products that have been manufactured using captured carbon. Replicating this at mass scale will be an enormous challenge, but the benefits will extend beyond the obvious environmental impacts, according to David Bott, head of Innovation at the Society of Chemical Industry (SCI).

“The new business model will aim to reduce the need for imported fossil fuel material,” he said. “Instead, the consortium will build a new, more sustainable supply chain whilst also mitigating waste emissions. The group will develop methods for using carbon captured from waste streams of other industries and transform them into affordable raw materials for consumer products.”

The full list of Flue2Chem partners is: SCI, Unilever, BASF, Tata Steel, UPM-Kymmene, Holmen, Croda, Johnson Matthey, The University of Sheffield, The University of Surrey, Carbon Clean, Procter & Gamble, Centre for Process Innovation, Confederation of Paper Industries, and Reckitt.

Radio wave weapon knocks out drone swarms

Probably. A radio-controlled drone cannot be completely shielded to RF, else you´d lose the ability to control it. The fibre optical cable removes...