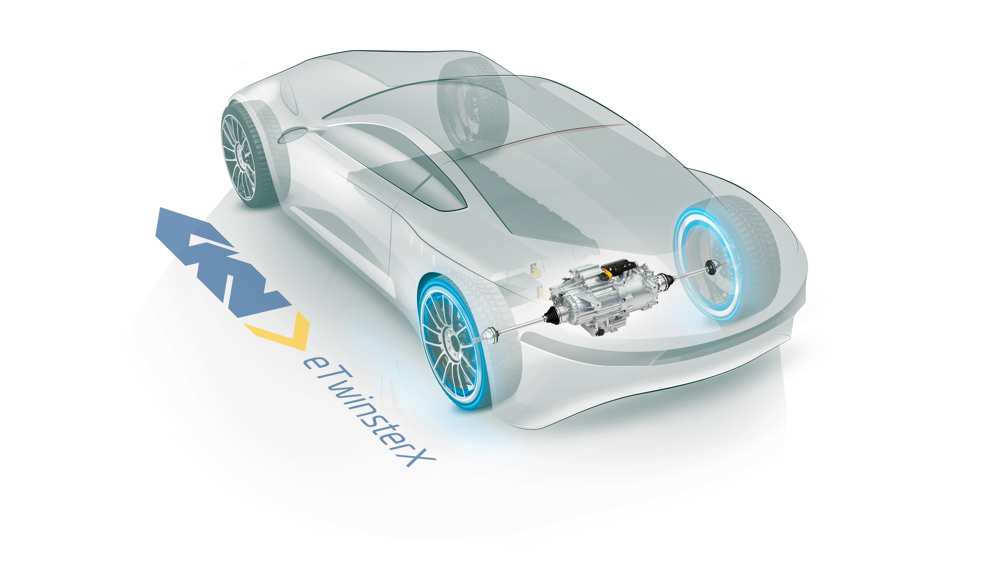

GKN unveils "world's most advanced" electric driveline concept

An electric axle concept for cars, claimed to be the most advanced system of its kind in the world, has been unveiled by GKN Driveline at the 2017 Frankfurt Motor Show.

Dubbed eTwinsterX, the system brings together a number of technologies already commercialised by GKN with some key new innovations that the company says could see the technology applied to a range of different vehicles.

According to the firm, the technology could be used either for the primary drive in fully electric vehicles, or for the secondary drive on plug-in hybrid vehicles – creating a ‘split-axle’ driveline. GKN has already supplied high-performance front eAxles for the Porsche 918 Spyder and BMW i8 supercars, as well as efficient rear eAxles for the Volvo XC90 T8 Twin Engine and BMW 2 Series Active Tourer.

Thanks to an integrated format, in which all of the powertrain elements share a common housing, the new electric drive unit is smaller than other systems, making it suitable for a range of vehicle types from city cars to off-road SUVs. The integrated design also means that the system is easier to install than multiple individual eDrive components.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Klein Vision unveils AirCar production prototype

According to the Klein Vision website, they claim the market for flying cars will be $1.5 trillion by 2040, so at the top end $1 million per unit that...