Current CFRP production often involves large, expensive tooling and complicated, time-consuming heat cycles. Fraunhofer’s approach, however, uses infrared radiation to apply heat directly to the material in a vacuum.

For the mould wall, the researchers have found a material that transmits infrared radiation in the desired wavelength range, without experiencing any significant thermal expansion. As a result, they claim, a part that could take several hours to cure with a conventional vacuum-based variotherm process can now be done in less than 60 seconds.

“Our method is faster, more economical and more energy efficient than the current state of the art,” said Sebastian Baumgärtner, mechanical engineer at Fraunhofer. “Processing in a vacuum protects the material. The plastic does not oxidise, as it does in open procedures. Trapped air and any gases are sucked out. The process is very stable and easy to use.”

All forms of electromagnetic radiation are suitable for heating CFRP in this approach, Baumgärtner explained, including microwaves.

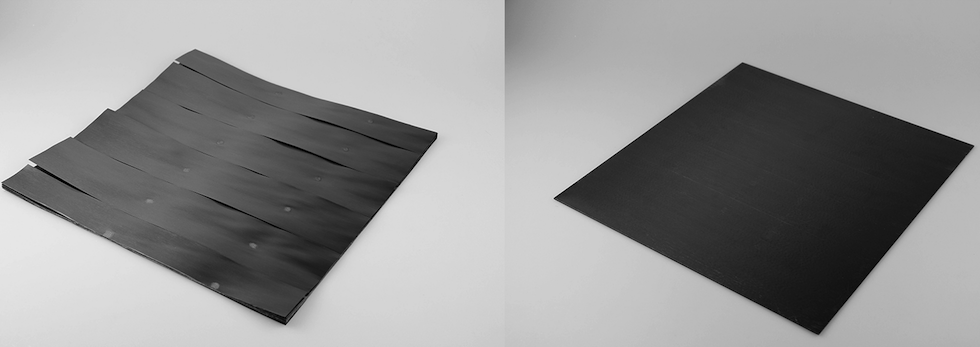

The system is described as being small enough to fit on ‘a normal shop floor’ with no large structures or special foundations. It’s also said to result in extremely low distortion.

“This is a major challenge when manufacturing with CFRP,” said Baumgärtner. “We heat and cool symmetrically, using a mould wall with minimal thermal expansion and operating at relatively low process pressures in order to avoid squeeze flow. The smooth surface of the mould wall also creates an almost reflective CFRP plate surface. This is a real advantage in the final component, particularly for applications in visible areas.”

The next step is to eliminate the use of the separating agent, which is currently used to remove the CFRP part from the moulds. At present, this tends to leave a residue on the parts, which can make further processing difficult, but the researchers are hoping to avoid this completely.

“Together with our colleagues from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials Research IFAM in Bremen, we are developing a special, durable separation layer and our goal is to apply this to our mould wall,” said Baumgärtner.

Fusion inches closer as ITER completes magnet system

I believe the purpose of ITER isn't to make usable power, it is a research project which will be used to design the first generation of actual...