The ‘biofibres’ can be dissolved into hot water in minutes to an hour. The researchers said that the aim is to dissolve an item of clothing, recycle the gelatine to make more fibres and, ultimately, create new clothing.

The study aims to tackle the growing problem of textile waste globally, as well as create new paths for fashion.

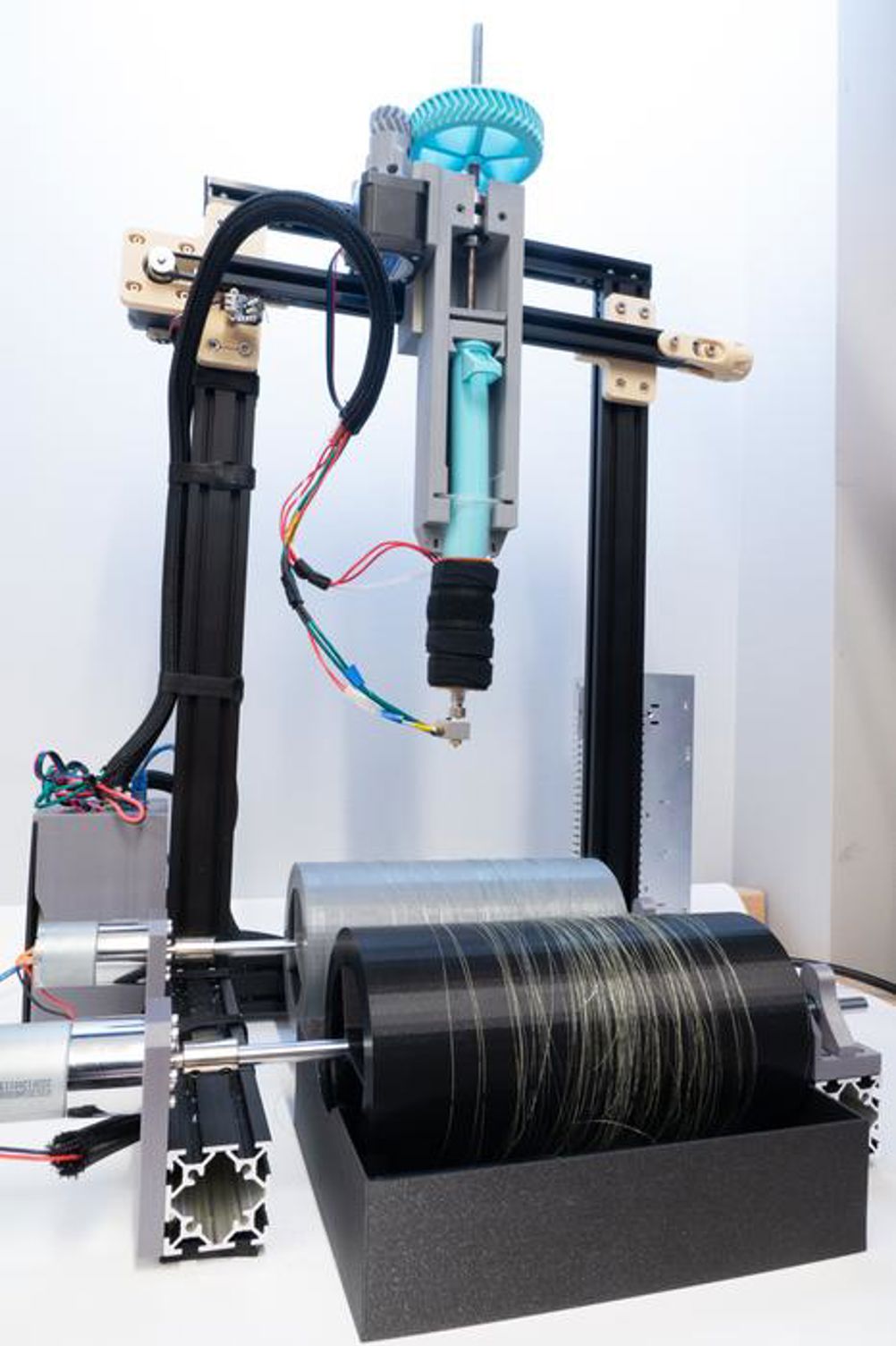

The researchers' DIY machine is small enough to fit on a desk and costs just $560 to build.

“You could customise fibres with the strength and elasticity you want, the colour you want,” Eldy Lázaro Vásquez, a doctoral student in the ATLAS Institute, said in a statement. “With this kind of prototyping machine, anyone can make fibres. You don’t need the big machines that are only in university chemistry departments.”

While the trend of ‘smart textiles’ – for instance, clothing that includes sensors that can connect to your smartphone – are impressive, the researchers said that the clothes are not yet recyclable, as it is difficult to separate the material from copper yarns and electronics.

To imagine a new way of creating climate-conscious textiles, the researchers began with gelatine. This springy protein is common in the bones and hooves of many animals, including pigs and cows.

Indeed, every year, meat producers throw away large volumes of gelatine that doesn’t meet requirements for cosmetics or food products – the research team wanted to turn this waste into wearable material.

The machine uses a plastic syringe to heat up and squeeze out droplets of a liquid gelatine mixture. Two sets of rollers in the machine then tug on the gelatine, stretching it out into long, thin fibres.

In the process, the fibres also pass through liquid baths where the researchers can introduce bio-based dyes or other additives to the material. Adding a small amount of fruit extract genipin, for example, makes the fibres stronger.

As a proof-of-concept, the researchers made small sensors out of gelatine fibres and cotton and conductive yarns. The team then submerged these patches in warm water, to dissolve the gelatine and release the yarns for easy recycling and reuse.

Lázaro Vásquez said that designers could adjust the chemistry of the fibres to make them a little more resilient, as ‘you wouldn’t want your jacket to disappear in the rain’. Designers could also experiment with spinning similar fibres from other natural ingredients – including chitin, a component of crab shells, or agar-agar, which comes from algae.

The research team, led by Lázaro Vásquez, presented its findings in May at the CHI Conference on Human Factors in Computing Systems in Honolulu.

The study can be accessed in full here.

IET sounds warning on AI doll trend

I agree that we need to reduce cooling water demand for servers. And yes, generative AI consumes a large amount. But what about BitCoins? Their...