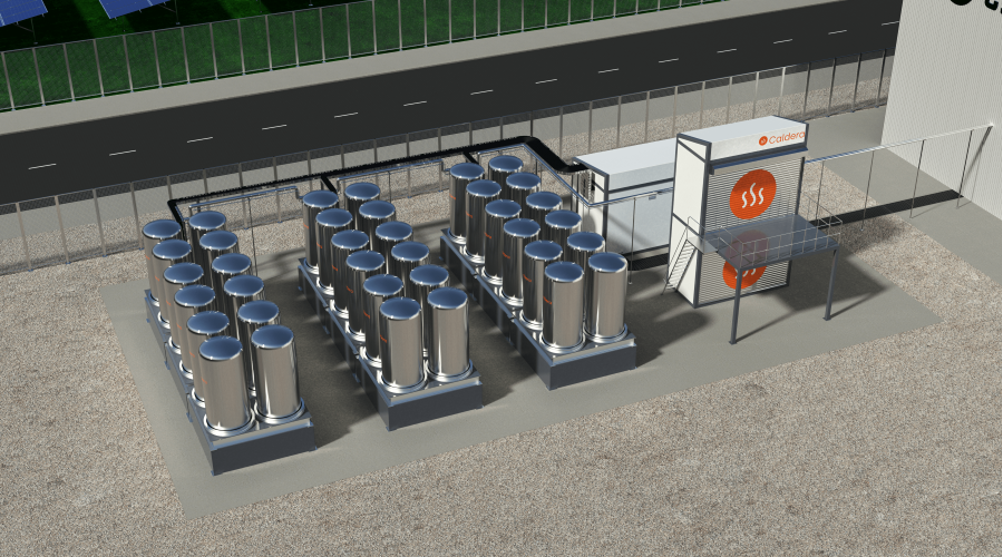

Founded in 2018, the startup has been developing its thermal storage technology over the past five years, initially targeting domestic heating with its Warmstone heat battery. Now the company is turning its attention to industrial heat, looking to scale up its technology. The £4.3m has been awarded via the Department for Energy Security & Net Zero’s Industrial Fuel Switching Competition and will allow Caldera to build a full-scale, industrial-size demonstrator at its Southampton site.

Related content

“Each heat cell contains a novel mixture of aluminium and either basalt or granite, which together make up 23 per cent of the earth’s crust,” said Caldera founder and CEO James Macnaghten. “We use scrap aluminium, which is cheap and abundant, and by combining these natural resources in the right way, we’ve created a ‘thermal super material’ which heats up phenomenally well and can store that heat for hours, ready to be released when required.

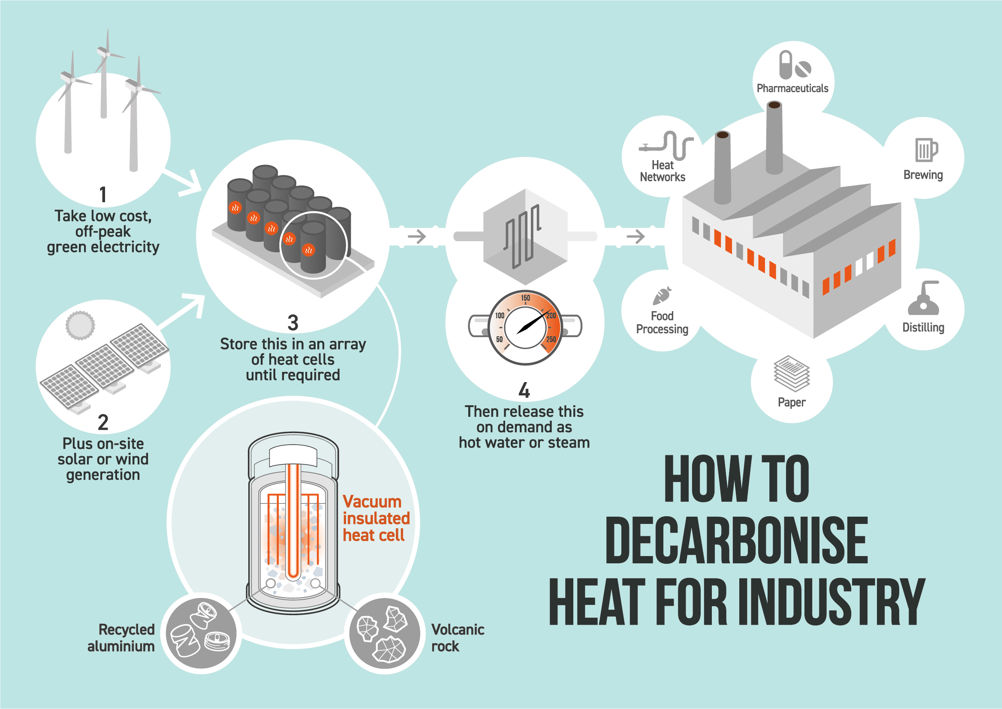

“Each system can be set to charge from the grid at night when cheaper and greener electricity is available, and can use on-site renewables, such as solar or wind. It can then rapidly deliver this heat as hot water or steam on demand.”

The Caldera electric storage boiler will use intelligent circuitry to enable smart switching from grid to solar or other low carbon sources. Each heat storage unit will comprise ten solid heat cells, each of which can store 200kWh, offering a total of 2MWh storage. These modular units can be scaled up to deliver as much capacity as needed. According to Caldera, work will begin this year and the project will complete in 2025.

“Decarbonising industry is a real challenge,” said Macnaughten. “British industry is a major user of heat, and industrial steam makes up 31 per cent of the UK’s total industrial heat requirement – typically in processes such as pharmaceuticals, food manufacturing and brewing.

“Typically, this is provided by steam boilers that burn gas or oil. In contrast, our electric storage boiler will comprise multiple cells which are heated by off-peak renewables and on-site generation. Each heat cell houses a solid core of aluminium-rock composite encased in vacuum insulation which can store heat at temperatures from 200 to 500C.

“These modular cells can store this with very high efficiency for hours, ready to deliver heat on demand at temperatures between 80 to 200 C – the sweet spot for many industrial processes. We can output high pressure steam, hot water, hot air or thermal oil, dependent on customer needs.”

According to Macnaughten, the volcanic rock/scrap metal combo behaves similarly to high-performance concrete, but with a much higher thermal take-up and resistance to stressing at high temperature.

“Our aluminium-rock composite can be thought of as super conductive, ultra tough concrete,” he said. “It can deliver heat 50 times more quickly than concrete, yet unlike concrete it does not crack when thermally stressed.”

Radio wave weapon knocks out drone swarms

Probably. A radio-controlled drone cannot be completely shielded to RF, else you´d lose the ability to control it. The fibre optical cable removes...