The group led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering, and Professor Dong Ki Yoon from the Department of Chemistry has developed a technique that can uniformly pattern gold nanorod (GNR) particles in quadrants through evaporation and have used this to develop the anti-icing and de-icing surface.

Scientists have tried to control substrate surfaces through various coating techniques, and those involving the patterning of functional nanomaterials are said to have gained special attention.

According to KAIST, GNR is considered a promising candidate nanomaterial for its biocompatibility, chemical stability, relatively simple synthesis, and its stable and unique property of surface plasmon resonance.

To maximise the performance of GNR, it is important to achieve a high uniformity during film deposition, and a high level of rod alignment. However, achieving both criteria has been challenging until now.

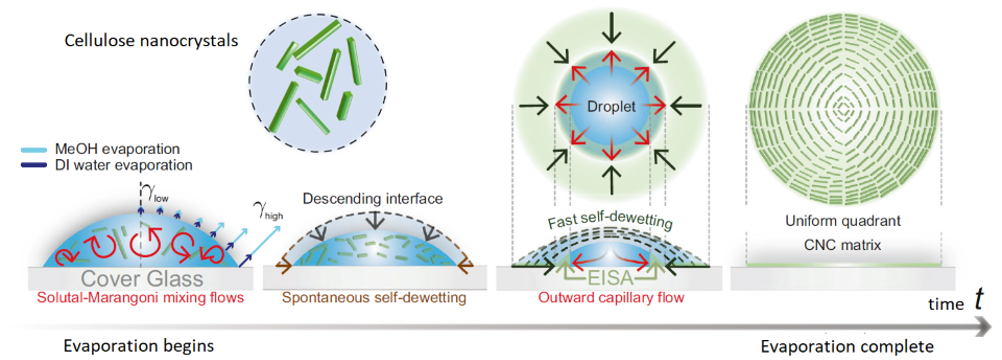

To solve this, the team utilised cellulose nanocrystal (CNC), a next-generation functional nanomaterial that can be extracted easily from nature.

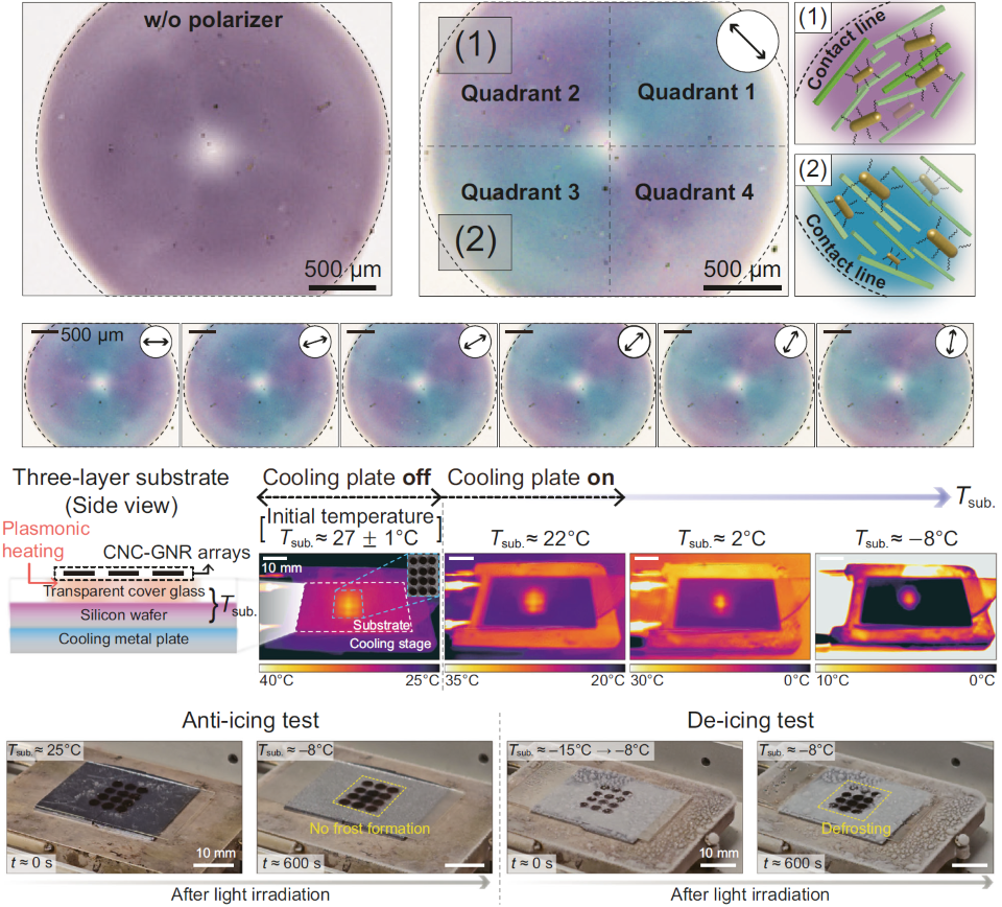

By co-assembling GNR on CNC quadrant templates, the team could uniformly dry the film and obtain a GNR film with a uniform alignment in a ring-shape.

Compared to existing coffee-ring films, the highly uniform and aligned GNR film showed enhanced plasmonic photothermal properties, and the team showed that it could carry out anti-icing and de-icing functions by irradiating light in the visible wavelength range.

In a statement, Professor Hyoungsoo Kim said, “This technique can be applied to plastic, as well as flexible surfaces. By using it on exterior materials and films, it can generate its own heat energy, which would greatly save energy through voluntary thermal energy harvesting across various applications including cars, aircrafts, and windows in residential or commercial spaces, where frosting becomes a serious issue in the winter.”

“This research is significant in that we can now freely pattern the CNC-GNR composite, which was previously difficult to create into films, over a large area,” said Professor Dong Ki Yoon. “We can utilise this as an anti-icing material, and if we were to take advantage of the plasmonic properties of gold, we can also use it like stained-glass to decorate glass surfaces.”

The team’s findings have been published in Nature Communications.

Guest blog: exploring opportunities for hydrogen combustion engines

"We wouldn't need to pillage the environment for the rare metals for batteries, magnets, or catalisers". Batteries don't use rare...