3D printed products replicate efficiency of mammalian movement

Animal physiology has inspired the development of a 3D printing method to produce shape-shifting liquid metal robotics with musculoskeletal qualities.

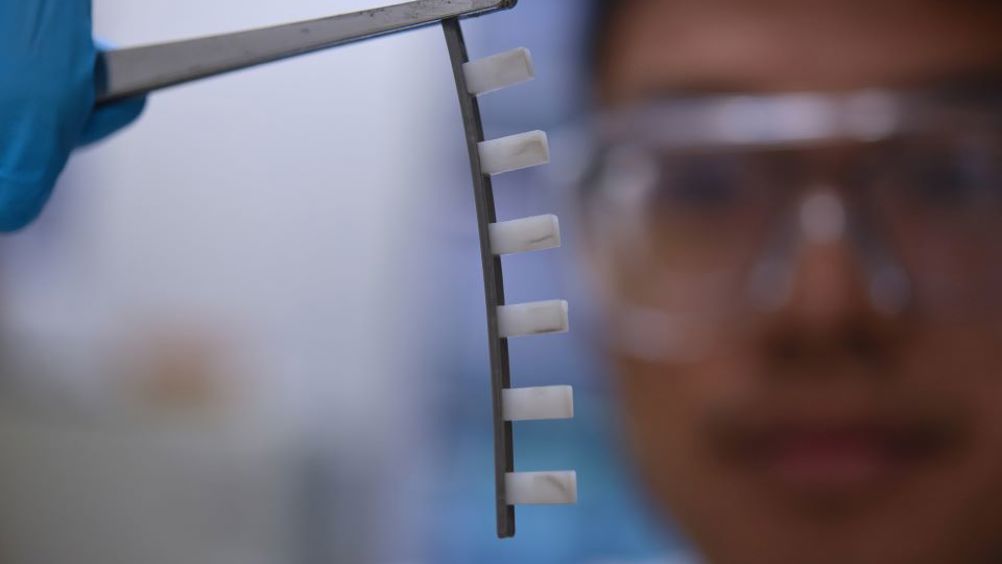

Dr Ruirui Qiao and her research team at the University of Queensland’s Australian Institute for Bioengineering and Nanotechnology (AIBN) have used the technique to make medical rehabilitation components and devices that are claimed to have superior strength and flexibility.

“We set out to mimic the locomotion, flexibility and control of mammalian movement,” Dr Qiao said in a statement.

“By combining ‘soft’ spherical liquid metal nanoparticles and ‘rigid’ rod-like gallium-based nanorods in the 3D printing process, we have been able to replicate the interconnected network of bone and muscle that gives animals an advantage in efficiency and strength.

“This tuneable gallium-polymer composite can be used for next generation medical rehabilitation products like high-precision grippers for prosthetic limbs.”

Similar to Dr Qiao’s previous work with liquid metal, the new creations can take and maintain different shapes and functions when exposed to stimuli such as heat and infrared light.

Dr Qiao said many manufacturers draw inspiration from the locomotion mechanisms of soft-bodied creatures in nature.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Fusion inches closer as ITER completes magnet system

I believe the purpose of ITER isn't to make usable power, it is a research project which will be used to design the first generation of actual...