Now, a European consortium has completed a three-year FP7 project to improve aircraft maintenance and repair processes by integrating health management capabilities with additive manufacturing.

A total of 12 partners, including Boeing and Lufthansa Technik, took part in the in the three-year RepAIR project. The fully tested RepAIR system is now looking for industry partners for further development and application in operational environments.

Cranfield University received £800,000 of the £5m total funding and focussed its efforts on health condition monitoring, the repair and manufacture of components through additive manufacturing, and certification.

Suresh Perinpanayagam, lecturer in the Integrated Vehicle Health Management (IVHM) Centre at Cranfield University fielded questions from The Engineer on the challenges presented during RepAIR and how the combined use of condition monitoring and additive manufacturing could lead to major cost-savings, reduced turnaround times and schedule interruptions, and less scrap wastage.

To put RepAIR into context, how do airlines currently approach fleet maintenance?

Nowadays maintenance is mainly reactive or preventive, many of the components are part of a Line Replaceable Unit (LRU) and if a failure occurs the whole LRU is replaced and the unit is sent to the hub to be inspected, repaired and installed in another aircraft.

The capability to repair a component using Additive Manufacturing (AM) can allow for a completely different scenario where parts are repaired or manufactured while the aircraft is on the ground, just requiring a certified metal 3D printer. In this way there are fewer delays and problems with the availability of aircraft. It reduces the need for keeping a stock of the full range of parts, and simplifies the whole logistics process.

A failure can be detected by the Integrated Vehicle Health Management (IVHM) of the aircraft, triggering the AM repair/traditional repair decision and the process to repair the faulty component by AM can start before the aircraft is even on the ground. Moreover, if AM capability is limited to certain hubs, the IVHM system will plan the maintenance action where AM technology is available.

However, achieving this vision means some fundamental changes to the established maintenance and logistics process - and the new technology needs to be certifiable by the relevant agencies (EASA, FAA)."

RepAIR proposes replacing aircraft components with new parts made by AM. Do you foresee any limits to a part’s complexity and will finished parts need finishing?

The limitations of subtractive manufacturing techniques are no longer a concern. However, limitations of AM should also be considered. Geometry complexity is not a concern, but thick parts may have thermal stresses and surface quality depends on the powder grain size.

Parts require a support, and the part should be removed from the support and the area in contact would require post-machining. High surface quality surfaces or tight tolerances may need additional material later removed by a conventional subtractive technique.

How does your condition monitoring system work and how will the end user the data it gathers?

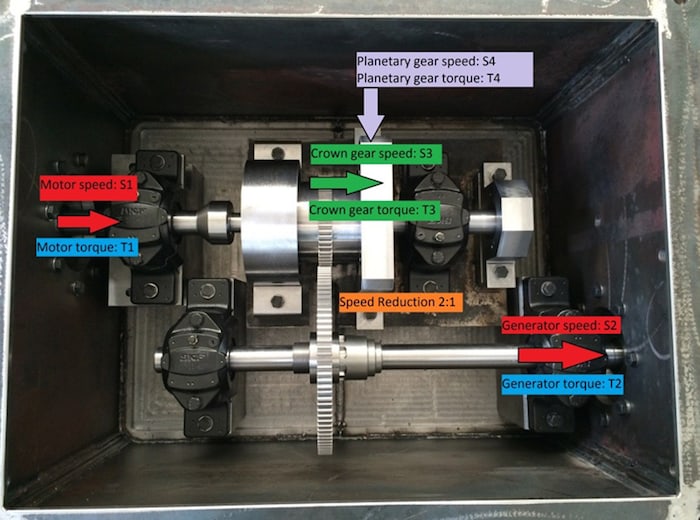

The health monitoring system proposed in RepAIr is capable of detecting a failure in the planetary transmission that connects turbine and generator by using a complex physics-based model for which no additional sensors are needed. The advantage of this system is that certification is simplified because no additional hardware is required.

The health monitoring system accesses data already available in the aircraft (speed, load, temperature) and calculates the friction. A failure alarm is triggered by a friction threshold, and a critical failure alarm is triggered if a higher threshold is reached. The system communicates the failure status (healthy, alarm, critical) along with the friction estimation and an identifier of the faulty component (flight, plane, component tag).

"The information is sent to the CAMO (Continuous Airworthiness Management Organization) and the pilot. The CAMO may decide to trigger a repair Work Order using AM or any other repair procedure. The pilot can act to minimize the damage by modifying the operational conditions of the transmission or disconnecting it if a critical alarm is triggered.

What is the certification environment like for AM parts?

Certification of AM for the aerospace industry is at the early stages. The authorities (EASA and FAA) along with the main stakeholders are working on the area. Therefore, it is not clear at the moment how certification of AM in detail will work in the aerospace industry.

RepAIR has focused on defining the qualification procedures required to apply for a certified process using the repair of the shroud as a case study. That is, what tests would be required during the manufacturing and repair process to ensure repeatability and quality of the repaired part.

What kind of savings could be made if RepAIR were widely adopted?

Due to AM there is a lower repair cost - no stock required and simplified logistics. There's the potential increased availability of the aircraft as there's no more delays from waiting for stock of the required parts to arrive.

There is a lower part cost, and lower environmental impact. AM parts can potentially be lighter and less material is wasted compared to subtractive techniques, reducing fuel consumption and environmental impact of the manufacturing process in general. Savings on inspection time; secondary damage is avoided because the component can be disconnected before total failure occurs, and total failure can be avoided by the pilot through the monitoring system, with the knock-on effect of avoiding a faulty component and the subsequent maintenance.

More details on the RepAIR project are available at the following address: http://www.rep-air.eu/

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...